Today, Apple SVP of Operations Jeff Williams attended a meeting with President Obama following the company’s adoption of the White House’s ‘SupplierPay’ initiative. The program, which also includes a financing component, is essentially an agreement by companies like Apple, Nissan, Rolls Royce and more to pay its small business suppliers faster — so that they can reinvest funds into growth.

SupplierPay is an evolution of QuickPay, which required federal agencies to pay small businesses within 15 days. SupplierPay applies this to the private sector, where manufacturers will fork over cash quicker to suppliers and investment companies will help them get lower-cost capital.

Basically, this is an attempt to get companies that can afford it to return cash flow to small or ‘diverse’ businesses quicker to let them spend that money, rather than it gathering interest in the coffers of a company like Apple.

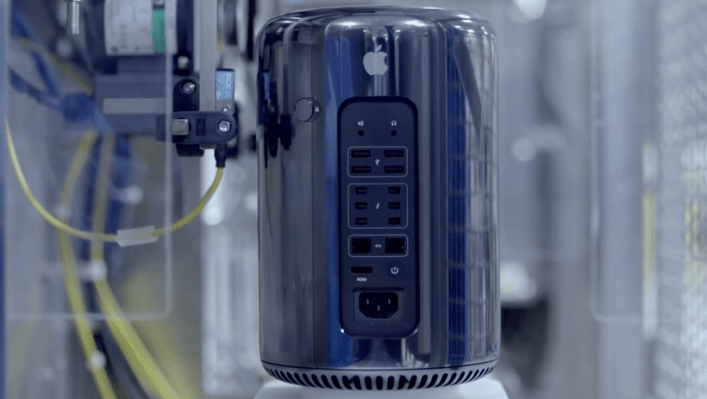

One of the case studies highlighted by the White House is Metal Impact, a company that mills aluminum, one of Apple’s favorite materials — and the company that manufactures the Mac Pro’s distinctive cylindrical enclosure.

You can see Metal Impact’s aluminum mill at work in Apple’s video about the making of the Mac Pro from last year.

“Last year, Apple spent more than $3 billion with over 7,000 suppliers running small and diverse businesses, creating tens of thousands of U.S. jobs,” the company said in a statement.

This is the first time Apple has released these kinds of numbers related to its U.S. supply chain, which it has been building out recently.

“We are proud to be making Mac Pro in Austin, Texas, partnering with dozens of component and equipment suppliers from 23 states. The first thing customers notice when they look at a Mac Pro is the revolutionary cylindrical aluminum enclosure which comes from Metal Impact, a small company in Elk Grove Village, Illinois,” said Apple in a statement.

Apple says that Metal Impact was primarily working with aluminum in the automotive space before it came to them about working on the Mac Pro.

“Alongside their team we created an entirely new process and supply chain, conducting more than 40 experiments with ten different alloys on multiple aluminum mills.”

Apple says that working with Metal Impact on the Mac Pro created 18 new jobs and millions in revenue to the Illinois company, which was founded in 1959.

Metal Impact credits Apple for aiding in its economic recovery over the past few years — during which they’ve tripled their business.

“Apple’s role in our recovery has been significant in both our financial results and, perhaps more importantly, the innovation they have provoked,” the company said in a statement. “Apple believed in us and has totally changed the way we look at our business today. Our work with Apple has inspired us to do things that had never been done before. Together we created an entirely new manufacturing process and have built something that we never imagined possible.

“We’re a tiny part of Apple’s incredible story but every time a customer looks at their Mac Pro, we hope they see the pride our team in Elk Grove Village put into making it.”

One factor to consider, of course, is that it is likely that some of those 7,000 suppliers actually outsource manufacturing or supply of their own to China — so not all of that money is staying here. Still, Apple contributing to the U.S. economy is good — and certainly makes for good PR at a time when the supply chain of tech giants like Apple and its rival Samsung have come under massive scrutiny.

The general thought behind QuickPay was that it would reduce costs to small businesses to the tune of ‘billions’ by reducing the amount of interest they paid out on loans taken to finance growth or continued manufacturing. The goal, of course, would be to generate economic growth without having to rely on Congress. Since 2011, QuickPay has generated ‘over $1B’ in cost savings for small contractors — at least according to the administration.

We’ll have to wait and see whether SupplierPay will generate similar gains for these small businesses. Jason Roys, president of consulting firm SDV International, told the New York Times that a major contractor of theirs, IBM, already pays faster than other firms. Still, faster would be better.

“We’re small and cash flow is a major constraint,” Roys said. “If we’re paid sooner, that would allow us to more quickly reinvest our earnings.”

Apple’s SupplierPay agreement is one component of an ongoing campaign to promote the company’s spending inside the U.S. These efforts have likely been accelerated by talk over how much manufacturing the company outsources to China, as well as the continuing back and forth over whether Apple pays its due taxes in the U.S.. Apple CEO Tim Cook has stated that Apple pays ‘every dollar we owe’.

In an interview with Politico early last year, Cook said that the company had made a $100 million investment in domestic manufacturing of what we now know to be the Mac Pro — and maybe future products.

“We’re going very deep in this project,” Cook said at the time, noting that some components would be manufactured in Arizona, Texas, Florida and Illinois, where Metal Impact is located.

Apple has also made a major investment in Sapphire glass production with GT Advanced Technologies, an Arizona company. That expanded Apple’s ‘Made In The USA’ efforts beyond silicon facilities it maintains in Texas.

Other tech companies that have signed on to the SupplierPay initiative include IBM, AT&T, Intuit, Ericsson and Philips.

Additional reporting by Jon Shieber.