Unless you work in manufacturing or product design, you probably haven’t spent a lot of time thinking about how plastic shapes are made. Look around you — see anything with a plastic casing? It was probably injection-molded, and the tool used to make the plastic was probably a royal pain in the ejector pins to manufacture. Atomic Industries is taking an industry that’s currently part science and part art, powered by skilled artisan toolmakers, and adding a layer of software to the mix in an attempt to make toolmaking cheaper, faster and more repeatable.

Today, the company announced it raised $3.2 million from Point72 Ventures, 8VC and Toyota Ventures to automate and evolve the existing workflows. At first, the software Atomic is creating will be for its internal use, but the plan is to eventually make it available to other companies.

Getting any product to market involves a number of steps that include product research and development. But once it gets down to the actual phase where you want to produce a prototype or move into the production of that item, you have to figure out how you’re going to manufacture it. Depending on the volume of parts that you need to make, tool and die making becomes a crucial role for pretty much everything that we use on a day-to-day basis. Toolmaking is incredibly complex — as Elon Musk points out, in many cases, the tools used to make plastic parts are more complicated than the parts they are making. Curiously, it’s often done by people who have a lot of experience and learned their craft through apprenticeship.

“You don’t typically go to college to learn this kind of stuff, and nobody really trusts you until you have gray hair,” notes Aaron Slodov, CEO and co-founder at Atomic Industries. “You have to know how manufacturable something is, and a lot of that has to do with the machinery that actually pumps out your parts. These machines have constraints, and the only people that really know how to apply those constraints are the ones that design the tool in the dye, or the injection mold, or whatever you’re using.”

The manufacturing tools are extremely costly, and a critical bottleneck in the production of most goods. Factories generally cannot produce parts without complex tooling (molds, dies, castings, etc.) engineered by skilled artisans whose knowledge keeps the industry alive. Atomic’s approach will introduce automation to traditional workflows that enhance productivity by orders of magnitude. The company is focused on reducing as many barriers in tool and die-making as possible. The team’s long-term vision is to make manufacturing accessible, scalable and repeatable. Automating tool and die making, the company posits, is a crucial part of that journey. The plan is to start with something valuable but a little less ambitious for now.

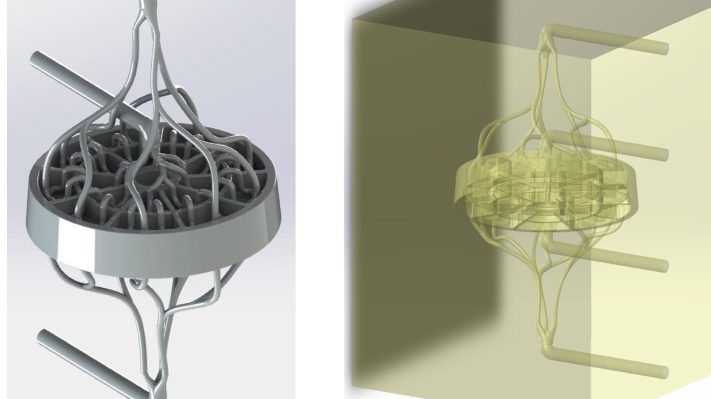

“A tool and die maker will generally receive a CAD file from a customer, for something they need to manufacture. Their task is to design the mold or tool for that part. You have somebody who designs this complex injection mold, which then has to be fabricated. Finally, it needs to be tested to make sure that parts that are coming out of that mold fit the specification of the customer’s needs,” explains Slodov. “They might specify very tight tolerances, for example. To do that, you have to have really good design, which is something that is driven by human intuition and experience a lot of the time.”

In a nutshell, Atomic is attempting to replace human intuition and the ineffable experience of an expert toolmaker with software that uses physics and algorithms.

“Instead of doing a simulation and then iterating that design, our software means that simulation and design all happen simultaneously. It’s orders of magnitude faster, and it’s more scalable,” explains Slodov. The scalable part is because software can parallelize a lot better than humans. “You cannot put more than one human designer onto a job; adding more designers doesn’t make it go faster in this type of work.”

Supply chains have gone under the microscope since the COVID-19 pandemic hit, and investors and startups alike have started to pay attention to industries and sectors ripe for disruption, and strong demand for new manufacturing technologies will continue to increase as supply chain issues persist.

“Despite being a fundamental process in manufacturing, tool and die making is an outdated, time-consuming, and labor-intensive process that has resisted innovation,” says Jim Adler, founding managing director of Toyota Ventures. “By leveraging software to automate the most difficult parts of the human tool and die designer’s workflow, Atomic enables a future where mass manufacturing is as agile and distributed as software development. The team’s expert ability to tackle this critical industry bottleneck is why we are so excited to join their mission to unlock the full potential of injection mold design.”