Flipping burgers is a hot and greasy job. Slips, trips, burns and cuts are common hazards associated with the work. But global demand for burgers is tremendous. Top burger chains racked up more than $75.5 billion in annual sales in 2016. To help keep human cooks out of harm’s way while fulfilling our collective appetite for burgers, Pasadena-based Miso Robotics is rolling out a new “robotic kitchen assistant” called Flippy.

Miso Robotics CEO and co-founder David Zito said, “We focus on using AI and automation to solve the high pain points in restaurants and food prep. That’s the dull, dirty and dangerous work around the grill, the fryer, and other prep work like chopping onions. The idea is to help restaurants improve food quality and safety without requiring a major kitchen redesign.”

Miso Robotics was funded in part by the quick service restaurant, CaliBurger, which makes and sells “California style burgers,” and operates in 12 countries today. Canyon Creek Capital and individual angel investors have also contributed funding to help Miso Robotics get started.

All of Miso Robotics employees went to work in CaliBurger kitchens as grill cooks before and while working on the original design of Flippy. Getting behind the grill and cooking with and without Flippy is a regular part of Zito’s job, the CEO said. Now, CaliBurger has committed to using Flippy in 50 of its restaurants, at least, over the next two years. It has already been testing Flippy in a Pasadena restaurant, the companies said.

The Flippy robot takes the form of a relatively small, wheeled cart equipped with a 6-axis robotic arm and what Miso Robotics calls a “sensor bar.” It can be installed in front of or next to any standard grill or fryer. It takes in data from thermal sensors, 3D sensors and different cameras onboard to perceive its environment. Digital systems that send tickets from the counter back to the kitchen give Flippy its orders.

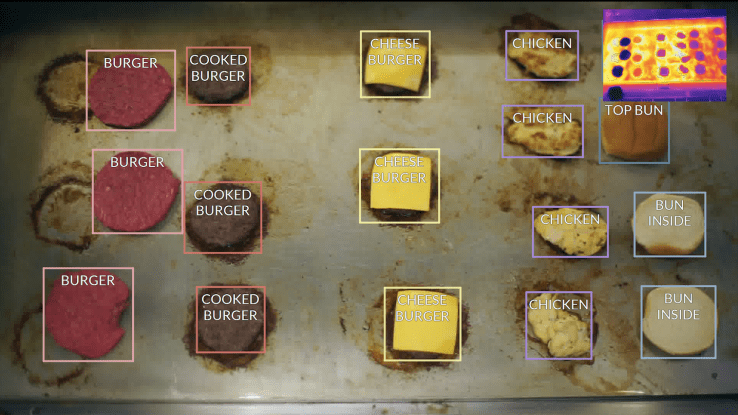

A robot’s view of the grill.

Among other functions, Flippy grabs unwrapped burger patties, moves them into position on a hot grill, keeps track of each burger’s cook-time and temperature, then alerts human cooks when it’s time to apply cheese or other toppings. Flippy plates burgers but doesn’t wrap them or add finishing touches like lettuce, tomatoes, avocado or a restaurant’s signature sauce.

Unlike other burger-making robots, including those made by Momentum Machines, Flippy is controlled by Miso Robotics’ AI software. AI and machine learning enable the robotic cook to learn to make new foods, adapting to a restaurant’s seasonal menu changes.

A range of different tools, like detachable grippers, tongs and scrapers, help Flippy to cook burgers made to order, and keep a grill operating smoothly. A pneumatic pump allows the robot to swap out its own tools. Combined with Miso Robotics’ AI, this range of tools will allow Flippy to make more than burgers over time, including chicken, bacon, grilled onions and other items that tend to be served in burger restaurants.

A burger-grilling robot called Flippy works alongside a human cook.

So, are cooks in commercial kitchens flat out of a job? If yes, that would affect some 2.3 million cooks employed, and too often underpaid, in the industry in the U.S. today. Zito acknowledges that commercial service robots like Flippy are handling more and more complex tasks than ever before, and seem poised to replace people who perform the most repetitive tasks at work.

But at the same time, the CEO said: “Tasting food and creating recipes will always be the purview of a chef. And restaurants are gathering places where we go to interact with each other. Humans will always play a very critical role in the hospitality side of the business given the social aspects of food. We just don’t know what the new roles will be yet in the industry.”