3D printing is in a bit of a doldrums. The novelty has worn off and the limited utility of the technology has been made clear. The bloom is especially off the rose of home 3D printing thanks to slow improvements in the actual technology involved in squirting plastic into clever shapes. There are only so many Yoda heads you can print before the 3D printer starts collecting dust.

But it must be said that behind the scenes things are improving incrementally in the space. Printers are far cheaper than they once were and they are now commonplace in school classrooms. Dreams of a 3D printer on every desk are going to take a bit longer than expected.

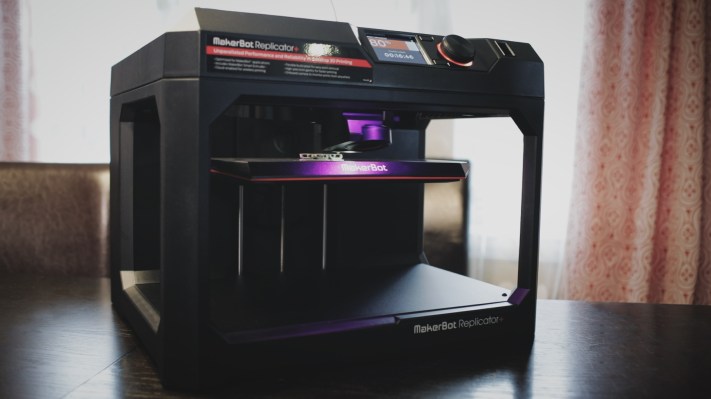

That hasn’t stopped Makerbot from trying to add a little more utility and ease-of-use to its latest Replicator and they have succeeded. The Replicator+ is essentially the Makerbot refined. It is an instant-on machine with zero learning curve and the software and Thingiverse model collection means that you’ll always have stuff to print. The resolution is more than acceptable and complex pieces come out beautifully detailed and immediately usable. It costs $1,999, still cheaper than competing “professional” printers, and it’s ready to use right out of the box.

How It Works

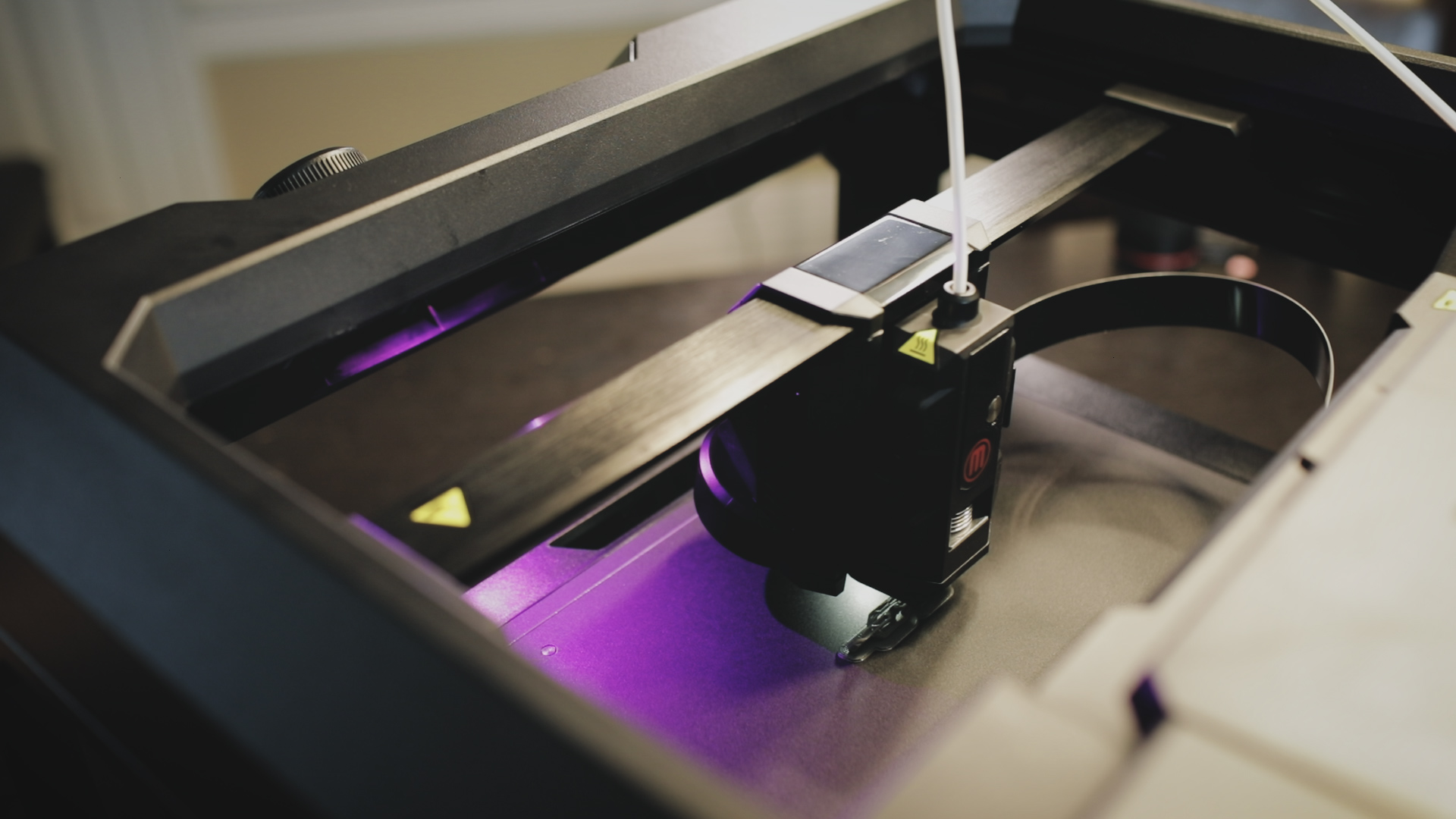

The Replicator+ prints PLA plastic, a form of plastic derived from starch. PLA is shown to release fewer potentially harmful vapors during printing, a major consideration when choosing a printer for a school or home environment. To use the filament you simply insert a spool into your printer and run the filament through a plastic tube. You then pre-heat the print head – a rectangular box that attaches magnetically to the robotic gantry inside the printer – and wait for the motor to kick in. You can then lead the filament into the print head and wait until it starts extruding. One button press later and you’re done.

The filament spool is hidden inside the printer itself and can be easily replaced with different colors. The Replicator+ only prints in one color unless you swap the filament mid-print.

The new printer software allows you to select and print models from Thingiverse right from your mobile phone, a huge improvement over the previous versions of the app. You can also print your own models from your computer. The desktop version of the app also offers more control over positioning and size.

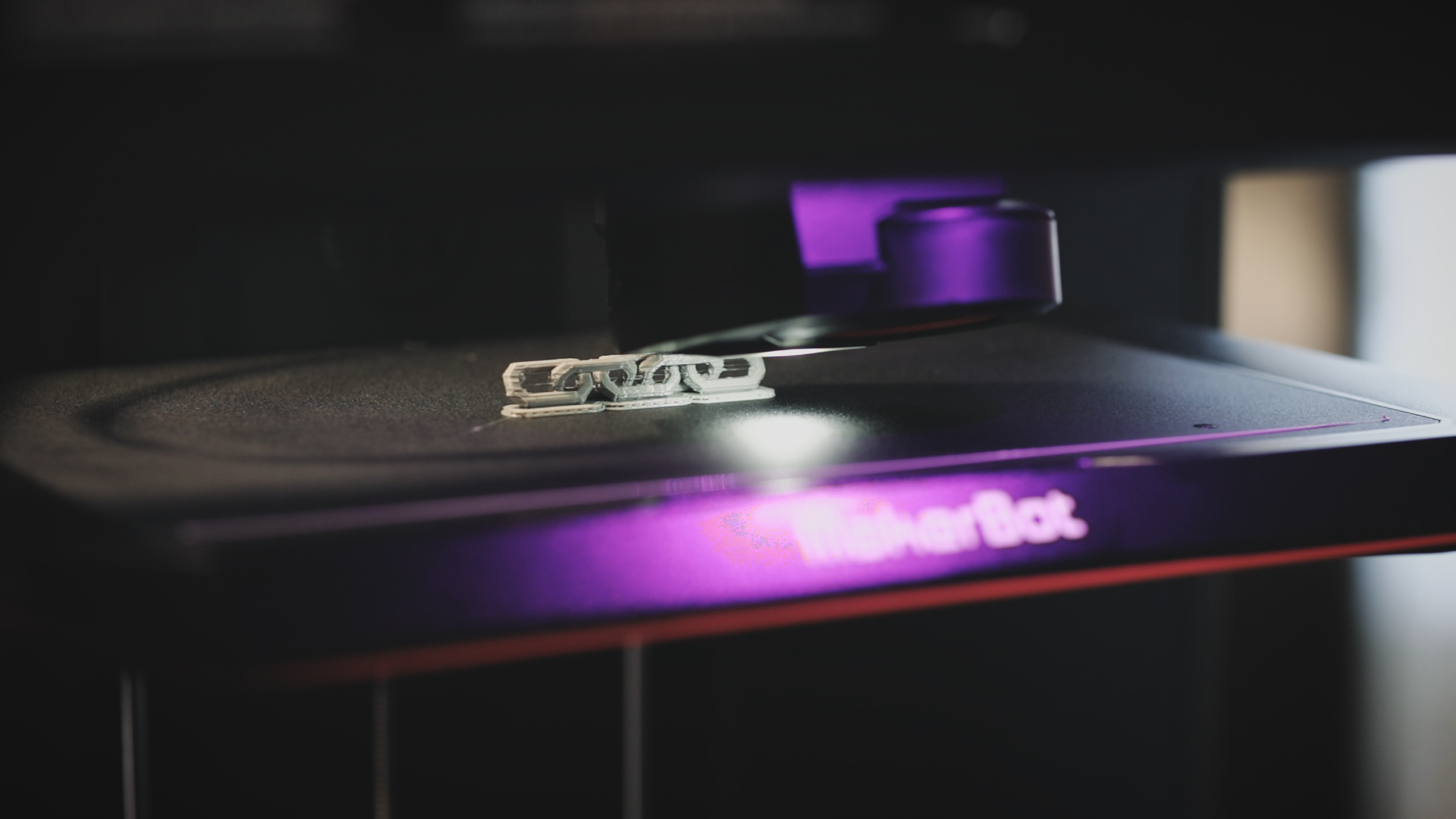

When the print is done the new print bed allows you to remove objects right from the plastic sheet. This is also a major improvement over previous glass print beds which were covered by a large piece of Kapton tape. This tape often ripped while removing prints, requiring a frequent repairs.

The new print bed is removable and flexible. This means you can bend and twist the bed slightly to get objects off of it and you rarely have to resort to scrapers. The prints I made didn’t quite come off without prodding but the fact that I didn’t need to replace any tape was a welcome change.

The printer is 30% faster than the previous Makerbot Replicator and there is a 25% larger build area – 11.6″ by 7.6″ by 6.3″ inches vs. 9.9″ by 7.8″ by 5.9″ inches. Printing speed is definitely improved in this model but complex projects can still take up to 20 hours to complete.

The Prints

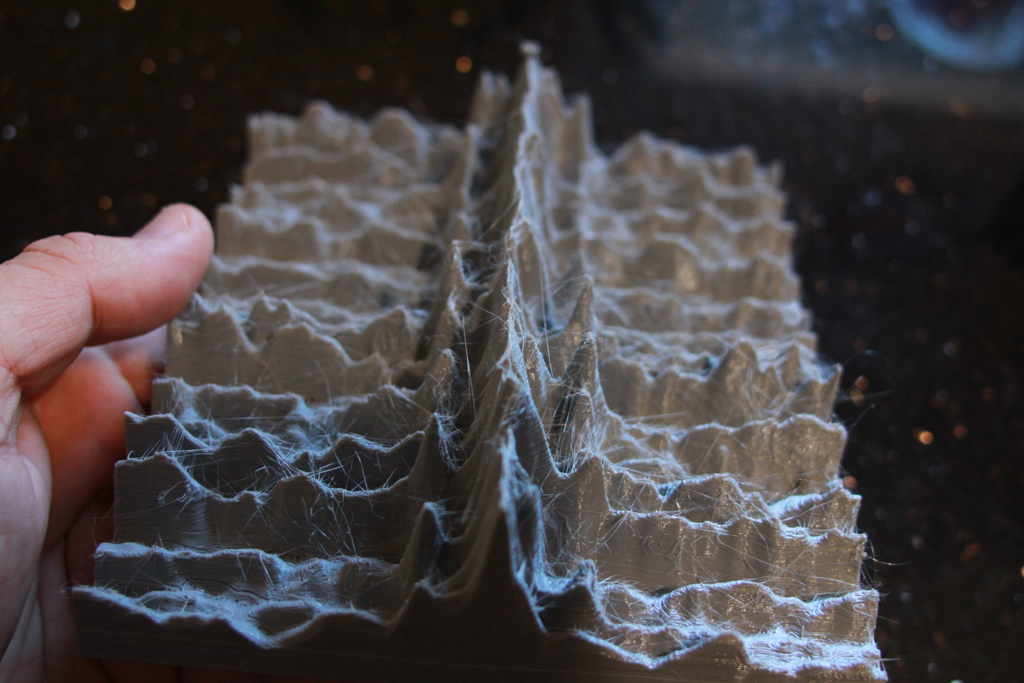

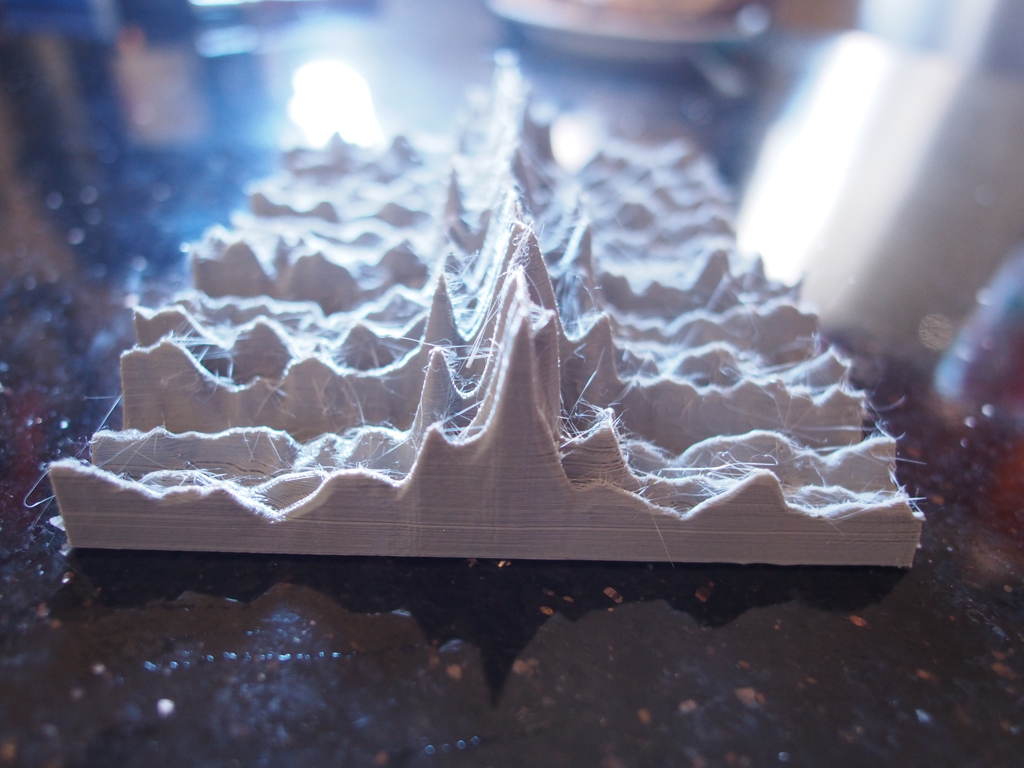

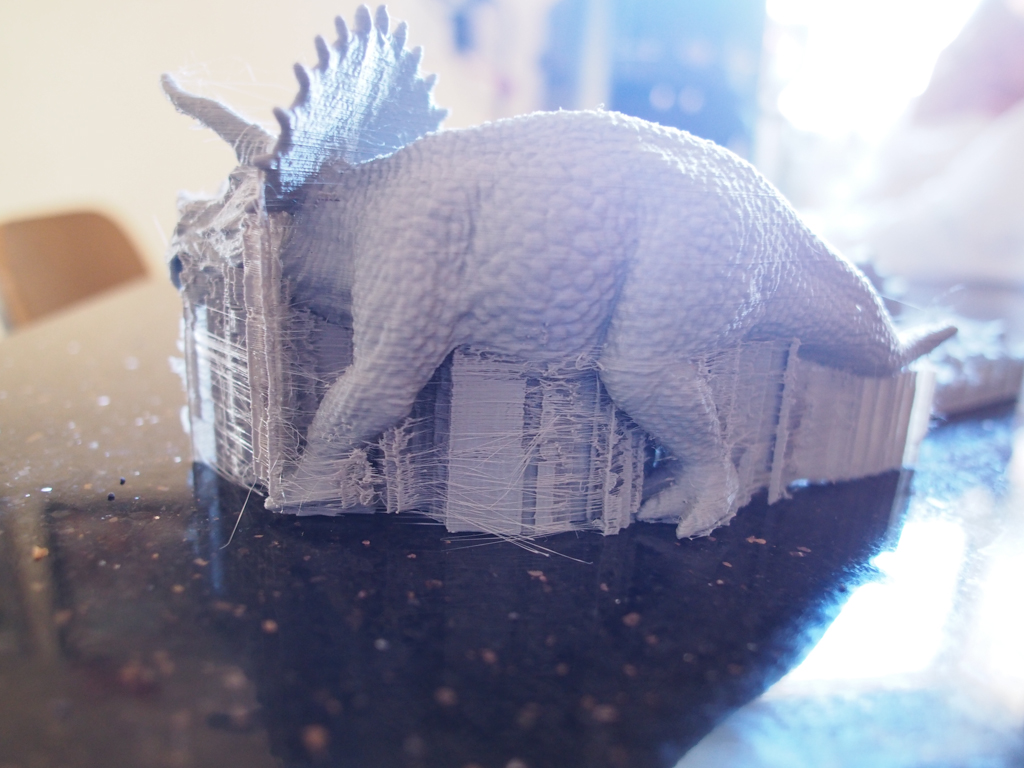

I printed two test objects on the printer. The first was a model of a signals from the pulsar PSR B0329+54 and the second was a triceratops. The pulsar was a big, complex piece and I wanted to see how long it would take to print – about 16 hours on a medium setting – while the triceratops had lots of open space that needed to be filled in with support material, another test of the printer’s ability to create complex objects with lots of detail.

As you can see the printer performed just fine in both counts. My major gripe? The new print head moves much faster than previous models thereby leaving a little trail of plastic from point to point. The result is a “hairy” model that you can fix with a lighter. These strands simply burn off. If you don’t want to deal with that you can also just rub the models down with a little sandpaper or meticulously pull the hairs off. However, this is my primary peeve with the new extruder and software.

The supports under the models were easy to remove – about on par with the original Replicator – but I found it difficult to pull the models off of the build plate, a fact that I’m sure will change over time as the build plate is used more and more. The build quality in general was excellent and the speed was definitely faster although the vagaries of slicing and support structures make it difficult to test the 30% claim outright. All I know is that it took about two hours longer to print that triceratops when I did it on the original Replicator.

In terms of physical durability of objects built don’t assume you can put any of these pieces in your car engine. I could see potentially using the Makerbot to print, say, a quadcopter propeller or dryer knob (true story) but anything more mission critical or needing structural integrity could be a problem. This 3D printer builds models that you can use to size, test, and envision. It doesn’t print finished parts except in very specific cases. Further, even though the layer height is quite nice here, you are still going to get the striations associated with this sort of 3D printing. If you need a perfectly smooth object you can get a Form Labs Form One printer, a product that products structurally coherent and smooth objects. This is a dot matrix printer vs. more expensive laser printers.

Can you have fun and learn from the Replicator+? Absolutely. Is it the best classroom printer by far? Yes. It’s easy to use, easy to maintain, and the software is still great. 3D printing and Makerbot has had its ups and downs but pound for pound their printers produce good things for not much money. It will be a long time before 3D printers become commonplace but it will be printers like this one that will soon find places of honor in our classrooms and workshops and the software alone is the gold standard by which all other 3D printers must be judged.