3D printer prices are falling steadily, something that shouldn’t surprise anyone familiar with the vagaries of the electronics market. What cost a few thousand last year is now hovering at less than a grand while knock-offs are going for around $500 or less, depending on the model. It’s a great time to be a 3D printing hobbyist. But are these new printers worth picking up?

I’ve used a few printers over the past year – Makerbot and Afinia included – and I was just given an opportunity to try out the Solidoodle 4, the latest printer from a Brooklyn-based company that offers bare-bones printers at acceptable prices.

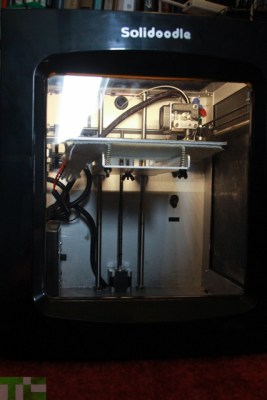

The Solidoodle, as the name suggests, is quite solid. It is completely enclosed with a powder-coated casing with magnetic doors and a closing lid, making it delightfully quiet. It has a large 8×8 inch build plate and can create objects up to eight inches high. It prints ABS out of the box but you can modify the software to print starch-based PLA. You level the bed with three wing nuts, two in the front and one at the back, and there is another screw that controls where the endstops hit.

The system is simple. It has a single extruder and a very primitive spool system that hangs off the back. You snake the filament into the extruder, push down the little lever that holds in the filament, and feed it through the nozzle. The controller is sealed in a plastic box to ensure it doesn’t overheat. A few fans keep it cool.

That said, it’s well worth the $1,000 price tag for the hardware alone. The company offers acceptable and swift support and the devices themselves are nicely built. But, as with nearly every low-cost printer, the software is abysmal.

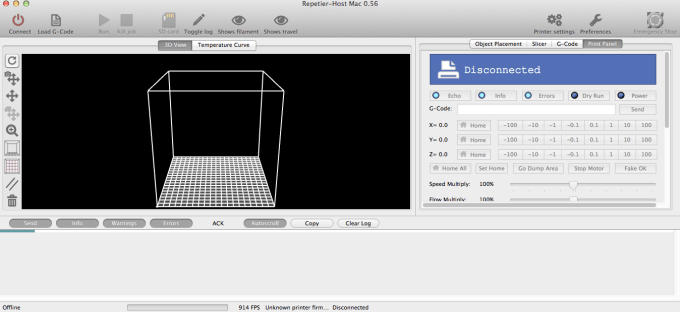

The system uses Repetier Host, a formerly open-source solution for RepRap printers. This software looks like a cross between the worst of Windows 95 bloatware and the stuff you see on the screen of high-end milling machines. It is software written by engineers and, because engineers like to be able to do all sorts of things, it features a four-way control for moving the print head, a few buttons for controlling the motor and a manual heating system that requires you to click a button to even begin thinking about printing. If your bed isn’t exactly level it will either smash the filament into the surface or extrude a string of loose filament. There is no sweet spot. This is not fire-and-forget territory.

Software is expensive. Makerbot spent millions on theirs and its Makerware, along with FormLab’s solution, is some of the best on the market. In short, it just works. You drag a file into the app, set your filament type, and press Make (the same goes for FormLabs’ solution, although it’s slightly more involved). Repetier, in theory, could do the same thing. You can place items, move them around with a very primitive text-based interface, and slice them using Slic3r, another open source app. Again, in theory, this should work fine. In practice on OS X, Windows 7, and Windows 8.1, the experience is awful. The nerds among you will tell me that all this can be scripted but if I’m a tinkerer buying a 3D printer for $1,000 I probably want something more that works out of the box, not something I have to piddle around with for days.

How frustrating is the software? Slicing takes minutes even on a fast machine. The system will sometimes run cold, which means neither the bed nor the extruder were hot enough to print. Extrusion thickness, if not set correctly, would cause print after print to fail and even after updating the settings with official Solidoodle specs it still failed. Fool me once, shame on me. Fool me twice and I won’t get fooled again.

There are many in the open source community who will disagree with my assessment but let me assure you that use of open source software, while inexpensive, will make or break your 3D printer experience. Open source is great when very little is on the line and you can get away with some wonky interfaces or when quite a lot is on the line and you can’t hobble mission critical software with closed source shenanigans. At this point in home 3D-printing’s gestation period, however, manufactures must offer as much hand-holding as possible. Anything less and you’ve just sold your customer a $999 paperweight.

To be fair you can produce some acceptable prints out of the Solidoodle. With a good model you can print nice objects at a nice resolution. To test the printer, however, I printed this “calibration model,” a large sheet with a number of balls, holes, and overhanging parts. As you can see, the resulting print was far from perfect but good enough, given the potential for failure at every step. The ball, as you see, came out fine while the holes with the small overhangs were rough. The main structure in the middle was the most problematic and the entire thing peeled off of the plate even after a liberal application of ABS slurry.

[gallery ids="967867,967866,967868,967865,967864"]

All told I was able to produce two usable pieces using the Solidoodle, and 99% of the problems were related to the software. I spent a full week with it, trying various configurations, and the company was more than helpful when it came to troubleshooting. However, it just wasn’t enough. If you’re a student on a budget and have plenty free time to futz with this desktop printer then you can probably get away with simply buying a cheaper RepRap clone and calling it a day. If you’re a designer or engineer, however, you could be wooed by the Solidoodle’s superior build quality and heating characteristics. However, once you fire up the software you’ll find yourself stymied. Is it impossible to use? No, but you’ll find it quite frustrating.

This is not to say that the Solidoodle isn’t a good printer. Compared to others I’ve seen and used it’s surprisingly robust and easy to use. However, as mentioned before, the software is the constant stumbling block. Makerbot, too, suffered from bad software fever a few years ago when it used Replicator-G but at this point every serious manufacturer of 3D printers should have their own solution until someone comes along and adds one-click printing from the CAD/CAM system of your choice. 3D printers are still in their infancy and software like this sets the industry back each time it is used.

Should you buy the Solidoodle 4? If you have plenty of time to work through the problems yourself, then by all means pick it up. It is quite a bit more expensive than, say, a similar open-source printer but the build quality alone makes it a good deal. Are you a 3D-printing novice? Then that’s a different story. In short, this printer isn’t for you… yet. With an upgrade to the software I could definitely recommend this model over similarly priced printers, if only for the enclosed build cavity. I gave this thing hours of my life and, while I will agree that I’m not a smart man, you’ll need the patience of Job to keep futzing with this printer until you get something good out of it. I honestly want a 3D printer in every home and this model shows great promise. However, as in almost every computing endeavor, software makes or breaks an experience. Hardware is hard, but software is far harder. I will follow up with the company as they grow in order to see just where their software efforts are headed.

[gallery ids="967857,967858,967859,967860,967861,967862,967863"]