There are about four duck boats lined up directly across the street from this coffee shop. Boston has a knack for reminding you where you are, should you get bonked on the head and suddenly forget what city you’re in. This is a far more truncated visit than the last time. Most likely as you’re reading this, TechCrunch Early Stage Boston will be well underway.

I carved out a bit of time on either side of the event to meet some of the folks I didn’t get to see last time. I’ve got a few universities, research institutes and startups on the list. I’ll jump at pretty much any excuse to get back to Boston and Pittsburgh these days (let me know if there’s a good one for the latter in the next few months).

Oh, and I’ve recently decided to swing by Detroit at the end of next month, so if there’s anything I definitely need to check out, let me know (accepting that our definitions of “definitely” may vary a good deal).

Heading over to MassRobotics shortly, after a recent Zoom call with Tom Ryden, the org’s executive director. I’d been wanting to talk interoperability since my recent trip to ProMat. It’s something I’ve regrettably not yet managed to highlight in any sort of meaningful way in Actuator, so we’ll be making up for that today.

As discussed the other week, along with autonomous mobile manipulation, cross-platform interoperability is a major holy grail for the industry. As companies increasingly push toward fully autonomous warehouses, the realization is no doubt quickly dawning that the goal can’t be achieved by relying on a single company.

Will the day come when robotics firms will offer true top-to-bottom solutions? Maybe? Getting there would take a long time and a hell of a lot of money — be it through in-house R&D or acquisition (likely both). From what I’ve seen, most ARM firms in the space are largely focusing on their current addressable market (which is admittedly massive), rather than rushing into additional segments of the market. Amazon’s certainly pushing for it, but economic belt-tightening aside, a fat lot of good that’s going to do all of the non-Amazon companies out there.

For the foreseeable future, increased automation means working with more robots from more companies. That presents the very real problem of interoperability. Put in the plainest language, you don’t want to suddenly find yourself tasked with running a warehouse of robots that don’t know how to work together.

There are a lot of companies working on fleet management software, which we’ve talked about in the past and will, no doubt, talk about again soon. This week, however, I’m interested in something I’ve written about a lot with my consumer electronics hat, but very seldomly with the robotics one (it’s shaped like R2-D2. Got it on discount after Halloween). So we’re going to be kicking things off with the Q&A, then some more VC survey results, job listings and then back to your regularly planned roundup.

Image Credits: Hi, this is a meme.

Q&A with Tom Ryden

TC: Why did MassRobotics take this problem on?

TR: We took this on a couple of years ago, when we were talking to a lot of the manufacturers and customers of AMRs. It was clear that there isn’t going to be one solution. There isn’t going to be one AMR that does everything. We were starting to see things like AMRs and robotic floor cleaners get out there and we heard from major customers saying, “This is a problem. We have all of these platforms. We have to somehow manage them all in a better way. They’re all independent and they don’t speak to each other.”

So we looked around and didn’t see anything. [We asked if] we could help and create a very low lift, very simple standard. It’s really a data exchange standard. Here’s a common way to broadcast information from each AMR and then we can have other companies develop software packages that display all of the different platforms and give you statistics on the systems and how they’re performing.

We released that about a year and a half ago. It’s a pretty simple standard. We’re working now on the next vision. That will add complexity. What we didn’t do in the first one is task management or “tasking.” There was no ability for third-party software to go in and control any of the robots. Part of that is because none of the AMR vendors wanted that. They all have their own traffic management systems. They all believe their traffic management systems do the best for their systems and are optimized for their systems. I don’t disagree. Now we’re trying to work on a way that there will be some ability to manage different platforms without interfering with their set directions.

You’re creating both the standard and the software?

No. We are trying to provide software only as example. Sometimes it’s helpful to get example code for how you would implement this. Our standard is more guidelines. If you adopt the standard, you can interoperate with other systems that are operating in the same area that you are.

What does it mean for them to communicate? I assume it’s not robot to robot?

They’re not doing it robot to robot. They’re just sending a broadcast for anybody who wants to read it. We have a standard communications protocol, so anybody that has the ability to gather that data can.

So I’m running a warehouse and now have something that allows them all to appear on the same map.

Correct. And you can see how all of the different vendors are operating on one system. The people who are developing the third-party software are getting a lot of different information about the robot. They can show how things are performing in your warehouse and gather different things that are helpful for the warehouse operator to understand.

VC Survey

Returning to the recent robotics VC survey, here’s this week’s question:

TC: How is robotics investing different than in previous years? What role have the pandemic, slowing economy and recent bank crisis had on your investments?

Kelly Chen, DCVC: The last few years have been a series of changing concerns as well as opportunities. After the major hardware supply chain issues, startups are learning to eliminate single points of weaknesses (i.e., bottlenecks to shipping products). This comes with sacrifices to the design and cost in the near term, but it will prepare robotics startups for strong and robust scaling in the long-term.

A slowing economy usually means corporate customers are less willing to make large capital investments to solve their short- to medium-term labor problems, but robotics startups are increasing pushing for a recurring pricing model (robotics as a service) or a price per pick model, allowing customers to pay with a smaller lump sum and OPEX over time.

As for the bank crisis, robotics startups often secure venture and equipment debt, so we are happy to see new banks step up to provide these types of services to the startup community.

Rohit Sharma, True Ventures: I think the exuberance of 2021 and 2022 has given way to more rational exchanges between investors and founders. There is a renewed focus on the customer instead of growth or pure-technology, and there is an element of excitement about how fast-developing techniques in the machine learning and AI domain might play a role in delivering more effective robots. On the customer interaction front, there is a bit more of a focus on what value it delivers to them, and how quickly is that value going to make a difference in the customer’s operations.

Kira Noodleman, Bee Partners: COVID-19 has urgently shown us a glimpse of a more roboticized, automated, resilient future of work that extends across the supply chain and beyond the mission critical. While this trend started in manufacturing, it has now moved well beyond into areas like healthcare, R&D, agriculture, waste management and many more.

Our current volatile economy has made investors demand asset-lighter, often software-powered hardware solutions that bear less risk given the increased nimbleness of said solutions. What feels new today in automation is how quickly and flexibly you can set up a system to work. And there is an increasing industry acceptance that if it is too expensive to automate, it might as well be not possible (because everything technically can be automated). Globally, shifts in recent years have added pressure to the U.S. to step up its game.

The average robot per 10,000 workers globally is 141 (source: IFR). In the U.S., we’re at 244 (above average), but there are six countries ahead of us: China just passed us (350), and the No. 1 is Korea (1,000!) — clearly they are a manufacturing juggernaut. Yet, the U.S. has the largest GDP in the world, and this feels unacceptable.

More next week!

News

Image Credits: Noah Medical

Here’s an extremely healthy round for Noah Medical. The Bay Area–based firm this week announced a $150 Series B led by Prosperity7 Ventures and featuring Tiger Global, along with Hillhouse, Sequoia China, ShangBay Capital, UpHonest Capital, Sunmed Capital, Lyfe Capital, 1955 Capital and AME Cloud. It probably won’t shock you to hear that it was an oversubscribed round.

But robots are expensive, and medical robots are very expensive. Noah’s flagship product is the Galaxy System, which is used to more accurate pinpoint nodules for lung biopsies.

“We are a mission driven startup and appreciate our investors’ support to allow us to scale and deliver on the future of medical robotics,” founder and CEO Jian Zhang said in a release. “Next generation robotics platforms like the Galaxy System are filling procedural gaps to provide superior clinical values to better serve customers’ needs. We are excited to welcome these investors to the team and are eager to grow and serve even more patients and clinicians.”

The funding was, no doubt, helped along by the fact that the system received FDA clearance last month. It has also begun human trials at Sydney, Australia’s Macquarie University Hospital.

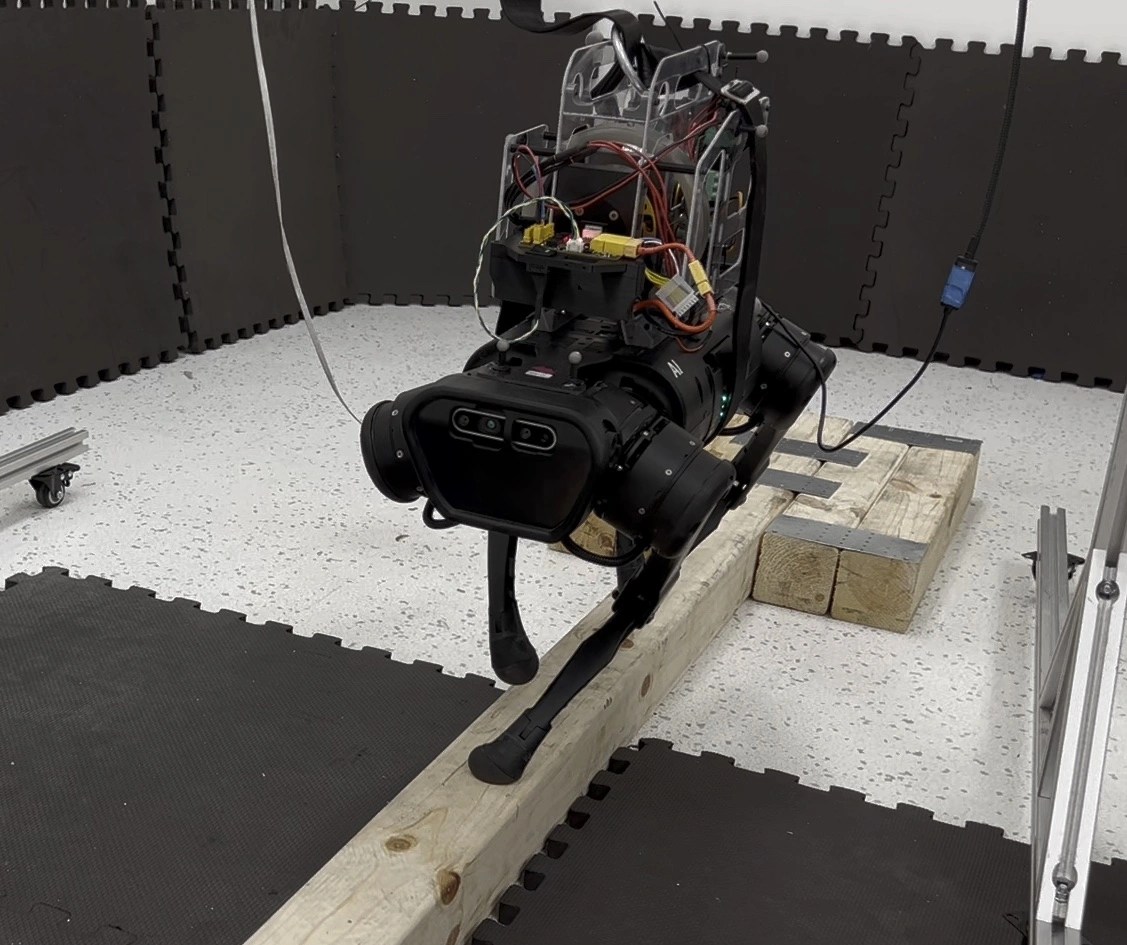

Image Credits: CMU

Search and rescue is a big applications for autonomous robotic systems. Legged robots are becoming increasingly more sophisticated and better at navigating uneven terrain, but there are still a number of scenarios that present issues. A team at CMU is tackling one, taking on these systems’ ability to balance on narrow spaces.

In the lab, that means teaching a dog robot how to walk a balance beam. The solution? Mounting a big flywheel to the dog’s back.

Says CMU:

Manchester said it was easy to modify an existing control framework to account for the RWAs because the hardware doesn’t change the robot’s mass distribution, nor does it have the joint limitations of a tail or spine. Without needing to account for such constraints, the hardware can be modeled like a gyrostat (an idealized model of a spacecraft) and integrated into a standard model-predictive control algorithm.

Jobs

And finally, some job listings. Here’s a form to get into next week’s Actuator.

Robotics jobs for human people:

Bear Robotics (57 roles)

Brain Corp. (12 roles)

Formic (12 roles)

Kewazo (8 roles)

Vecna Robotics (3 roles)

Image Credits: Bryce Durbin / TechCrunch

Subscribe to Actuator. Come on, work with me on this.