The starry-eyed founder story usually goes something like this: Start an earthbound company, make lots of money, launch a rocket company to go to Mars.

If that’s the stereotypical narrative, then Chris Graves has it all backward.

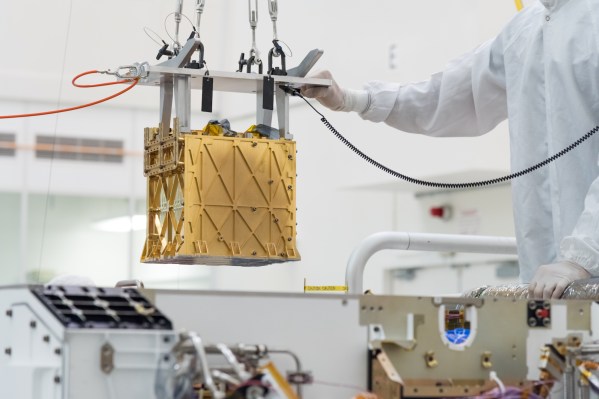

Graves started with the Red Planet, helping to develop a key instrument for NASA’s Perseverance rover that’s currently roaming the Jezero crater. That instrument inspired him to invent a novel battery technology that today forms the foundation of his startup, Noon Energy.

On Mars, the MOXIE instrument is intended to test the viability of making rocket-ready oxygen on Mars to enable return trips to Earth, saving mass on the outbound leg of the trip. The device sucks in carbon dioxide and strips off an oxygen atom, which it stores on board. The remaining carbon monoxide is exhausted into the thin Martian atmosphere.

Here on Earth, Noon’s carbon-oxygen battery is targeted at larger-scale applications to help bridge intermittencies that naturally occur with wind and solar. It runs a modified version of the same chemical reaction as MOXIE, though the goal is to store electricity rather than produce oxygen.

At its core, both MOXIE and Noon use a type of reversible fuel cell. Depending on the direction of the reaction, it’s called a solid oxide fuel cell or solid oxide electrolyzer.

In Noon’s version, the battery starts off with a full tank of carbon dioxide. Perhaps counterintuitively, this is the discharged state. To charge the battery, electricity flows through the battery, performing two chemical reactions. In one, it turns carbon dioxide into oxygen and carbon monoxide. The second reaction, known as the Boudouard reaction, strips the oxygen atom from carbon monoxide, leaving oxygen, which is exhausted, and solid carbon, which is stored. The second reaction gives off heat and the first reaction absorbs it, so after the initial startup, the system is neatly balanced.

To discharge the battery, the same reactions are run in reverse: Oxygen is drawn in from the atmosphere and carbon is withdrawn from storage. The electricity that results from the reactions gets sent to the grid (or wherever else it’s to be used), and the carbon dioxide gets stored in the tank.

Graves was coy about the specifics of the process and the nature of the catalyst used in the electrolyzer/fuel cell, but he said it uses fewer critical minerals than a lithium-ion battery of equivalent capacity. The same is true of the tank that stores the solid carbon.

The links between Noon’s technology and the MOXIE instrument on Perseverance are no coincidence — Graves helped design the experiment while he was a professor in Denmark.

Today, Noon is announcing a $28 million Series A round led by Clean Energy Ventures and Aramco Ventures, with participation from Emerson Collective, At One Ventures, Mistletoe, Doral Energy-Tech Ventures and others.

Given that Noon’s technology can use carbon dioxide — and that it could also produce fuels from the greenhouse gas — the connection with Aramco Ventures isn’t surprising. The corporate venture arm of the Saudi oil giant has been investing in a number of startups that put carbon dioxide to use.

Ultimately, though, Noon’s technology is focused more on energy storage than carbon dioxide management; after the first tank is hooked up, it doesn’t consume any more of the gas.

Graves thinks Noon can ultimately get the cost of its carbon-oxygen battery down to “well below” $20 per kWh. That’s about a fifth the cost of lithium-ion batteries and on par with projections for other technologies, like iron-air batteries and flow batteries, that are also targeted at large-scale applications. It’ll also be about as efficient as lithium-ion batteries, Graves said, and double that of hydrogen fuel cells when used as batteries.

Unlike many other systems, Noon’s tanks and solid carbon storage media are removable and could be trucked around to provide backup power where it’s needed, similar to diesel used for generators today.

Currently, the company has a working prototype and will be using the new funding to expand the team and build demo-scale systems that can be tested under real-world conditions. If all goes well, Noon will deliver the first system to customers in about two years.

“The scientific risk is fully behind us. We’re at a decent engineering scale,” Graves said. To get to market, Noon will be hiring a lot of engineers. “We need some really good people that have done that sort of scale up. We’re going to be hiring a lot and working hard on that.”