IndieBio (part of SOSV) is a biotech investor and accelerator that has started shifting more and more toward climate tech in recent years. The current cohort is batch 13, for fall 2022, and we’ve taken a closer look at the five that stood out the most.

IndieBio tells us that this batch is going big on diversity, both in terms of gender and geography. The cohort attracted companies from four countries — Brazil, Israel, Turkey and the U.S. are all represented — and 62% of the CEOs in this batch are women. Perhaps predictably, there’s less diversity in the education levels of the IndieBio founders, with 17 Ph.D.s, and all founders hold advanced academic degrees.

The companies are extraordinarily health-forward, with nine focusing on the health of the planet and four tackling challenges in human health. They’re approaching the problems from a bunch of different angles, including materials, foods, industrial biotech, therapeutics and diagnostics.

In a post-pandemic world, the accelerator has seen some changes to its program, too. Before 2020, all companies were expected to travel to San Francisco for four months, but those days are gone. Today, the 13 cohort companies are part of a hybrid program.

“It’s more than just the money,” managing director Po Bronson said in an email to TechCrunch, highlighting the accelerator’s “smart money” chops, “although the fact that we doubled our investment offering to $525,000 doesn’t hurt.”

Let’s take a look at the five most interesting companies in this IndieBio cohort — and what we love about ’em.

West~bourne — Zero-waste packaged food brand

Image Credits: West~bourne

Picked by: Haje

What they do: West~bourne started out as a zero-waste restaurant in New York. The founder, Camilla Marcus, went on to create a zero-waste consumer packaged goods (CPG) brand. The new company is sourcing all of its ingredients from regenerative agriculture, which is a philosophy that aims to create sustainable food production, as opposed to what a lot of industrial agriculture finds itself doing. The company creates baking mixes, sauces and snacks.

Why we like it: Adding organic ingredients to old recipes and calling it a day is so common that you can swing a garden hose in any direction and find 15 brands doing just that. Regenerative ag is a story that’s rare enough to be compelling in a VC context. Of course, the company is entering a fiercely competitive market, and it’s going to be interesting to see if West~bourne can sufficiently break through the wall of marketing noise to find its way to the hearts and minds of its target customers.

Other players in this space: There aren’t a lot of CPG brands that have embraced regenerative architecture, but it’s coming. Last year, German company Klim launched a software solution to help farmers transition, and 99 Counties is creating a marketplace for meat farmers using regenerative practices. Cooks Venture, meanwhile, founded by Blue Apron co-founder Matt Wadiak, is trying to make chicken farming greener by relying on regenerative ag to grow cleaner feed.

Gozen Bioworks — a leather alternative

Image Credits: Gozen Bioworks

Picked by: Haje

What they do: Turkey’s Gozen Bioworks is bringing a new type of “leather” to market, which it calls Xylozen. The company describes it as “twice as strong as animal leather, incredibly soft and easy to scale.” The product is meant to replace lambskin, particularly, which is used in high-end applications in the fashion industry, such as bags, coats, gloves, hats and boots. According to her LinkedIn, the company’s founder, Ece Gozen Akin, used to be the sustainability brand ambassador for Nike and is an experienced fashion designer.

Why we like it: Leather is often seen as a byproduct of food production, and it’s a common argument that if animals have to die for food, anyway, then why not just use the other parts, too? I do believe in not wasting anything, but I reject the argument that animals have to die for humans to eat, and products like this are a welcome addition to the landscape.

Other players in this space: There’s a lot of competition in the alternative leather space, including mycelium (MycoWorks raised $125 million to grow that market segment), and tech hipster favorite Allbirds just announced a plant-based leather alternative as well.

Minus Materials

Image Credits: Minus Materials

Picked by: Tim

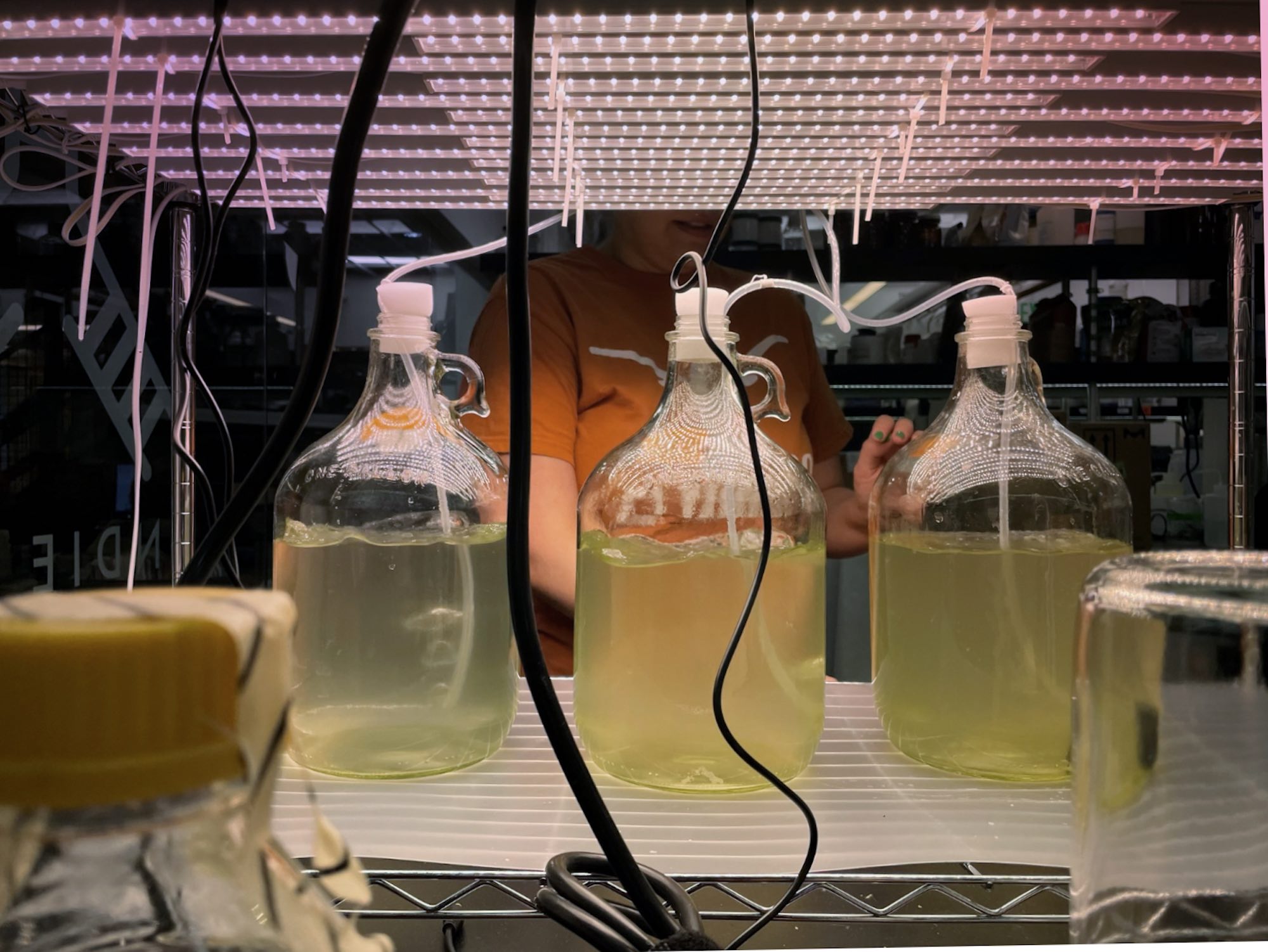

What they do: Minus Materials is making concrete using living things. Rather than mining limestone to produce cement, the company is using algae to turn carbon dioxide into limestone, a technique developed by founder and CEO Wil Srubar III, an associate professor of civil engineering at the University of Colorado Boulder. The company estimates that its process can trim up to 60% of the carbon emissions from a typical concrete-making process.

Why we like it: The concrete industry has an enormous carbon footprint — to make one pound of concrete, nearly a pound of carbon dioxide is released. Altogether, it’s responsible for at least 8% of the world’s carbon emissions, most of which come from cooking limestone to produce cement. Eliminating that source would go a long way to mitigating climate change.

Other players in this space: The way we make cement hasn’t changed much in the last 150 years or so, and myriad companies see room for improvement. One potential competitor, Prometheus Materials, was also started by Srubar. Another is Carbix, also an IndieBio company, as is Maa’va (see below). Others include CarbonCure, Brimstone Energy, Solidia, Blue Planet, Carbicrete and Fortera.

Maa’va

Image Credits: Maa’va

Picked by: Tim

What they do: Maa’va replaces the sand used in concrete with plastic waste. The company says that using its aggregate and process to make concrete is cheaper, reduces water use, allows the concrete to cure faster and reduces the end product’s weight by 40%.

Why we like it: Concrete production isn’t just a massive source of carbon pollution, it also consumes a massive amount of sand — over 3 billion metric tons per year — much of which is drawn from rivers, streams and shorelines. Replacing sand doesn’t directly diminish the climate impact of concrete, but it does reduce pressure on carbon-sequestering, biodiversity-enhancing ecosystems around the world.

Other players in this space: Same as Minus Materials (see above).

Mirá

Image Credits: Mirá

Picked by: Tim

What they do: If you’ve ever bought something from Ikea, you’re familiar with MDF (medium-density fiberboard). Furniture companies and builders like it because it’s cheap, smooth, uniform and stable. Typically, MDF is made by compressing wood fibers with a resin binder that essentially glues the fibers together. Mirá, though, uses an enzyme that causes the lignocellulose in the fibers to bond together at the molecular level, eliminating the need for a resin binder. The result, the company said, is more resistant to moisture and more readily recyclable and biodegradable.

Why we like it: Most binders are synthetic and contain formaldehyde, which off-gasses when MDF is new and contributes to poor indoor air quality. Plus, they cost money, and Mira says that it can make MDF with higher margins because it doesn’t have to buy the binder. It’s currently expanding its manufacturing facility in Brazil to produce 5,000 boards per week, and it has its sights set on other engineered woods that are increasingly used throughout the construction industry.

Other players in this space: 3RT, based in Australia, uses a proprietary water-based, formaldehyde-free resin and process to produce engineered wood made from waste and pulp that mimics boards from whole wood. Massachusetts-based Forust has developed a way to 3D print engineered wood that’s bound using a bio-based resin.