COVID-19 will be remembered for many things — most undoubtedly negative. There are, however, some silver linings among the horrors of the deadliest pandemic in recent memory. Among them, if the sort of human ingenuity that shines whenever the world is faced with a similar crisis.

The simple truth of the matter is the world wasn’t prepared for a virus of this magnitude. It’s something that’s played out in country after country, as the novel coronavirus has continued to devastate communities across borders.

In spite of early warning signs, many nations — the U.S. certainly included — were caught off-guard, lacking the proper personal protective equipment (PPE) and other necessities required to battle the virus for a prolonged stretch. For many, taking on COVID-19 has required improvisation and resourcefulness — both, thankfully, qualities found in good volumes among the maker community that helped give rise to 3D printing technology.

If you’ve followed the technology even in passing over the last decade, you’re no doubt aware how much time evangelists spend justifying the usefulness of 3D printing beyond the the confines of desktop hobbyists. The defensiveness is certainly understandable. Consumer 3D printing has all of the trapping of an overhyped boom and bust. The truth of the matter is that it simply wasn’t ready for the mainstream moment many investors and members of the press were ready to thrust upon it.

But even as desktop 3D printing companies begun to scale back or shutter at an alarming rate, the industry has continued to have success stories among those who have further innovated and targeted the right market. Formlabs jumps out amongst the desktop market, with Carbon presenting a success story on the industrial side of the fence. What unites both beyond innovation is a focus on real-world case uses.

When desktop 3D printing was on the ascent, I had more conversations than I care to remember about scenarios where the technology could some day come in handy. A common story was one of a broken oven knob — certainly something to which all or most of us can relate. Wouldn’t it be great, the idea goes, if we could simply pick it out from a catalogue and print the replacement up at home.

Yes, of course it would. Obviously. But the truth of that story was always several key steps away from the reality of what these largely FDM-based 3D printing systems were truly capable of. When it comes to investing $500 or $1,000 in a home machine, that’s just too large a gulf to cross. One thing the industry has largely lacked is tangible real-world examples. Formlabs, Carbon and the like have offered some fairly compelling examples in recent years, from sneakers to Invisalign braces to prosthetics.

Building on recent advances, COVID-19 could well be a flash point for the technology — or, at the very least, the evidence skeptics have been waiting for with regards to 3D printing’s usefulness. It’s not so much that the technology is suddenly useful in ways it wasn’t previous. Rather, this marks a return of serious discussions around the tech following a fall from grace that left many supporters licking their wounds.

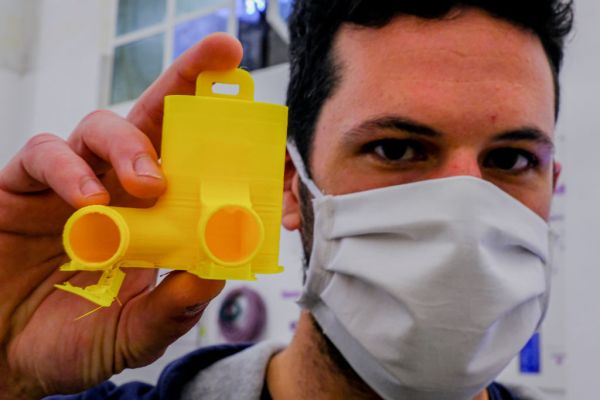

When COVID-19 arrived on our shores, many in the maker community mobilized across a broad range of different mediums. The biggest example is probably the push to produce cloth face masks to combat a shortage of surgical and N95 masks in the U.S. It was equally heartening to watch as the 3D printing community and companies united.

A paper published in Nature back in May outlines the phenomenon nicely.

As the cost of manufacturing equipment such as 3D printers and electronic components has dropped in recent years, this movement has permeated both formal educational settings and at-home hobbyist circles. Thus, in essence, this movement formed an extremely distributed and agile global network of manufacturers with widely varying capabilities. This network is a naturally occurring component of the maker culture. During the course of this pandemic, the members have focused on tackling three key areas: worker protection, disinfection and healthcare devices. Their success is due, in large part, to an existing ecosystem that was established prior to COVID-19.

It also notes the already-established National Institutes of Health 3D Print Exchange. The open source library, which hosts “biomedically relevant 3D models,” added a “COVID-19 response” section, which features a remarkable collection of things like 3D printable face masks and shields.

This week, the FDA noted that it was teaming with the NIH and makers to help address the PPE shortage. The effort comes as its work with the VA clinic has produced 272,000 3D-printed face shields and 230,000 3D-printed masks. “The FDA is working in partnership with the NIH, VA and America Makes to support nontraditional manufacturing approaches, such as 3D printing, to address device shortages including personal protective equipment (PPE),” it said in a release. “Through this partnership, 3D-printable designs for COVID response are given a clinical assessment by the VA and the NIH posts them on the 3D Print Exchange. FDA has, among other things, provided information on labeling and testing for face shields and face masks.”

Companies, too, have happily joined in. As we noted in May, Formlabs was awarded an emergency use authorization (EUA) from the FDA for 3D-printed valves that can effectively convert BiPAP machines (for sleep apnea) into ventilators, which were (and will likely continue to be) in short supply in overtaxed hospital systems. Two months prior, the company announced an FDA Class I exemption for its COVID-19 testing swabs.

HP is working with government and health agencies to produce a wide range of products, from face shields to ventilator parts. MakerBot, too, announced its own initiative, noting that it is, “working with Columbia University Libraries and Tangible Creative to produce, assemble and deliver face shields to NYC hospitals and health care workers on the front lines. As part of this effort, we are part of COVID Maker Response, a coalition of makers who are responding to the COVID-19 pandemic by manufacturing, assembling and distributing 3D-printed protective gear and other parts to frontline medical workers.”

It’s a pretty staggering mobilization, all told. I don’t recall seeing this much cooperation across the industry. There’s a lot of power in the realization that you’ve been sitting on an extremely unique solution to an utterly devastating problem. It seems likely that many smaller 3D-printing outfits will be irrevocably damaged from COVID-19-related shutdowns, but those that do survive may well come out the other side with a newfound sense of purpose.