Ah, supply invoicing. As a lad my dear old father used to dandle me on his knee and speak of the great supply invoice systems of yore. He came from an era when supply managers were giants, men and women of valor.

“Don’t go tryin’ anything new in Logistics, wee Johnny,” he’d say, pipe tobacco dribbling onto his sweater. “The old ways are best ways, that’s sure.”

But he was wrong. A new company called InstaSupply aims to prove that.

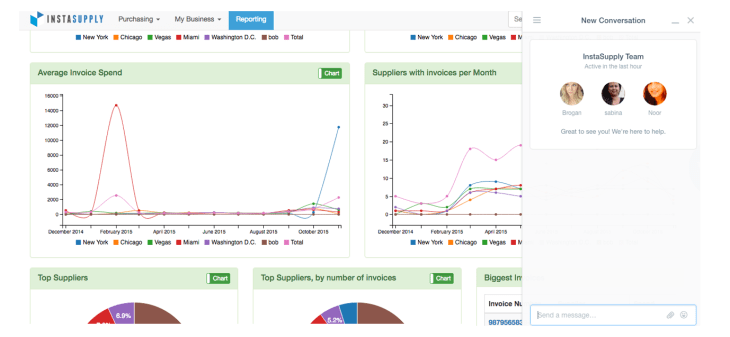

Procurement is all about paper. Order sheets fly from one end of the city to the other and most procurement is still done in carbon copy. InstaSupply is trying to pull all of those logistics off of the page and onto the computer.

Founded by Lee Pruitt and Tim Huegdon, formerly of W.W. Grainger and Amazon, respectively, the company has raised $1.5 million in seed capital in London. They have 2,700 users with 2,600 transactions per month so far. The system is cloud based which means that procurers and sellers can connect with each other in their own warehouses, and in a way reminiscent of a social network.

Interestingly the company is looking at the blockchain to register “proof of activity” for invoice payments, purchase orders, and the like.

“We found enterprise software was not only clunky but dull and impersonal too. Our core customer base are multi-site businesses with no/small procurement department in place, and have typically raised private equity, searching for ways to scale without adding extra staff,” said Pruitt. “We wanted to use technology to make life at work easier and enable companies to grow and thrive, not waste time and serious money on redundant manual processes.”

While the system isn’t as sexy as, say, drones dropping VR glasses over the Playa it’s important to remember that the most interesting problems are the stickiest. Logistics hasn’t changed much since the 1900s – it’s gotten faster and more streamlined, sure, and you can track a widget from factory to front door with ease. However, when it comes to the back and forth of buying a dozen crates of oranges every week, nobody has quite figured things out.

“Orders placed with suppliers are over the phone, via email, or a multitude of various supplier websites that result in the bulk of invoices received mostly in paper format to a detached finance department,” he said. “Our platform puts more eyes on the job to match orders with invoices. It’s all about working smarter.”

In the end will my Pa, the old logistician, ever abandon his old ways? Not likely, but then he doesn’t have to get a gross of frozen carp from Maine to New York anymore.