Building things is hard. It’s so hard that early stage capital deployed to hardware startups consistently makes up less than 3% of venture capital investments according to the WSJ.

With Fictiv, Dave and Nathan Evans want to combine engineering expertise with rapid prototyping to bolster the industry. In the process, they might just convince an investor or two that hardware doesn’t have to be risky.

Dave Evans first identified the need for more efficient prototyping while working for Ford. He sent three emails to a single prototyping shop; one from his Stanford.edu, one from his Ford email address, and one from his personal Gmail. The prices and estimated times for delivery were radically different for each identical request.

Dave Evans first identified the need for more efficient prototyping while working for Ford. He sent three emails to a single prototyping shop; one from his Stanford.edu, one from his Ford email address, and one from his personal Gmail. The prices and estimated times for delivery were radically different for each identical request.

“There is this huge prejudice in the ecosystem and at first you want to be angry at the vendor,” said Nathan Evans, Co-Founder of Fictiv. “But then you step back for a moment and see what incentivizes them to act in this way. For the vendors, it’s the Fords that pay the bills.”

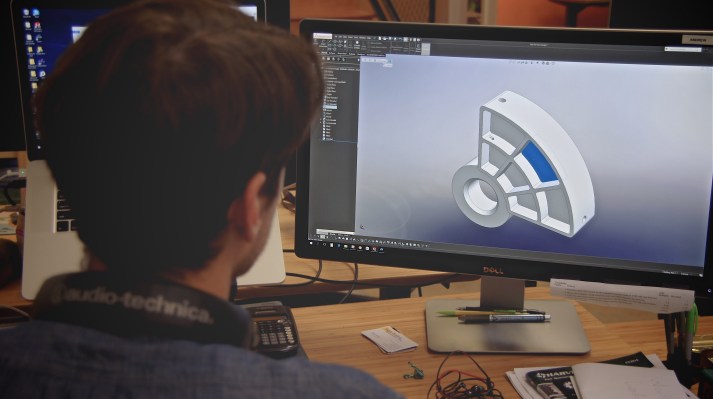

Fictiv strives to give every company the power of a player like Ford. The company created a two sided platform that is used by machine shops and designers. Machine shops upload availability and designers upload CAD files. Fictiv aggregates orders and routes designs to open machines.

“Some folks believe in cutting humans completely out of the loop on the manufacturing side,” added Dave Evans, Co-Founder of Fictiv. “We take a much different approach. The operator that runs the machine, you can’t replace someone with 30 years of experience. We just want to make him or her as efficient as possible.”

Fictiv guarantees prototypes for additive 3D print jobs in 24 hours. Today the company is launching rapid prototypes of CNC subtractive prototyping with a three-day turnaround.

Companies like 3D hubs and Shapeways might offer cheaper prices than Fictiv but are ultimately geared toward different users. Fictiv is targeting commercially viable products that can’t be produced on hobbyist level 3D printers.

Designers who want to rapid prototype with Fictiv don’t ever come in contact with the machine shops producing their designs. Fictiv’s value proposition is as much production knowledge as it is utilization data. The Fictiv team includes hardware engineers who can help anyone with a CAD design produce a prototype.

“There are plenty of things we design where I don’t really know if we can design a feature to a specific tolerance and I just toss it over to Fictiv and just ask if it’s possible,” said Scott Steber, Director of Engineering at Radicand.

Because Fictiv aggregates small jobs, over time it is able to exercise influence in the market. If the company does $500,000 a year with a vendor they start to have the power of a company like Ford. Fictiv has a two-week on-boarding process where potential fabrication shops print test parts and dial in their process.

Security is paramount when prototyping cutting edge parts. Fictiv is the only point of contact for designers. Other platforms have customers pair up with individual printers which can become a security issue. Fictiv regulates information disclosure on a need-to-know basis and deals in NDAs. The company has honored requests to split up production of parts across printers for further secrecy.

Fictiv is creating a hardware community in the heart of San Francisco that can learn and experiment together. The team is working to build relationships between builders and designers to incentivize local creation. Their website has a library of videos and explainers on common questions that come up when designing hardware.

Fictiv has lowered the barriers to entry for rapid prototyping. Moving forward, the company must grow community knowledge and machine capability equally to scale successfully.