Earlier this month, Hyundai acquired a controlling stake in Boston Dynamics that valued the company at $1.1 billion. What’s most interesting about the news isn’t the acquisition itself (it does, after all, find Boston Dynamics switching hands for the third time in seven years), but rather what the company’s evolution tells us about the state of robotics in 2020.

When the Waltham, Massachusetts-based startup was acquired by Google in 2013, it was still a carefully cultivated mystery. That the internet’s response to the company was largely one of curiosity shaded with discomfort should come as little surprise. Boston Dynamics’ primary output from a public relations perspective was viral videos of impressive but imposing quadrupedal robots built with the aid of defense department contracts. It doesn’t take a giant leap to begin coloring in the gaps with dystopian sentiment.

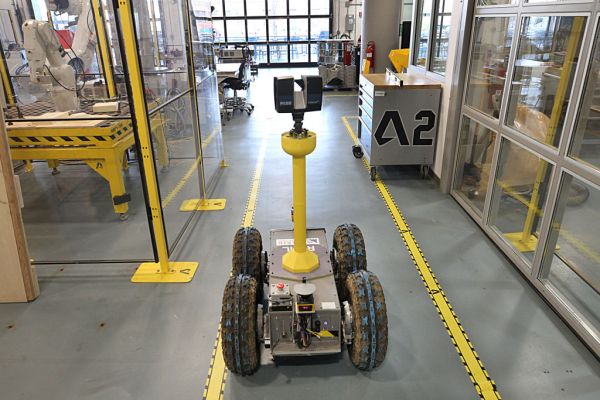

In instances where robotic deployment has been successful, the technology has helped ease the burden on an impacted workforce.

Some of that has continued to follow the company, of course. Even in the age of short attention spans, one doesn’t quickly forget an image of a man in a fleece vest unsuccessfully attempting to kick over a headless buzzing robot in an empty parking lot. Heck, to this day every post I do about the company is greeted with multiple gifs of the knife-wielding robot from the “Metalhead” episode of “Black Mirror.”

While the company is still committed to its more bleeding edge R&D concepts, Hyundai didn’t purchase a strange little MIT-spinoff that makes viral internet videos. It purchased a company actively working to monetize those efforts. As CEO Robert Playter told me in a recent interview, the company has sold 400 Spots since opening initial availability around 15 months ago. It’s not a huge number, but it’s a sign that interest in the company’s products extend well beyond novelty.

Spot’s primary task at the moment involves surveying dangerous workplaces, from nuclear reactors to oil rigs. Boston Dynamics’ next product, Handle, will move boxes around a warehouse. That robot is set to go on sale at some point in 2022. “I think something like a robot every couple of years is a pace that we could manage,” Playter told me. “From clean sheet, we can build a new robot in under a year. “And then you have to go through an iterative process of refining that concept and starting to understand market fit.”

Maturity in this industry requires a level of pragmatism. Tasked with describing the state of robotics in 2020, I would probably say it’s something like, “Cool technology employed for uncool tasks.” You can, no doubt, identify exceptions (making special effects for movies like Bot & Dolly is decidedly cool), but on the whole, Boston Dynamics is a perfect example of impressive robots doing boring stuff. Any roboticist will happily hammer into you the concept of the three Ds — the dull, dirty and dangerous jobs where the technology is most likely to be deployed.

See also the example of Agility Robotics. The Oregon State spinoff took a similar approach with the launch of its ostrich-inspired bipedal robot, Cassie — another viral video hit. Two years later, Cassie’s followup, Digit, was hanging out at the Ford booth at CES, pulling boxes from the back of a van. Nine months later, the startup announced a $20 million raise, bringing its total funding up to $29 million.

Investing interest in robotics and automation is not a new concept, of course. But there’s always been a question of whether the technology is mature enough, whether there’s a big enough need and if companies are willing to make the often-steep upfront investments for whatever payoff might come down the road. One of those concerns, at least, has been laid to rest over the course of the past 12 months.

No doubt we’ll be unpacking the lessons from the COVID-19 pandemic for the rest of our lives (and beyond). One of the immediately apparent learnings, however, was just how fast a virus can ground the global workforce to a screeching halt. We’ve seen a number of viruses in our lifetimes, but none can compare to the size and scope of COVID-19. Society designated a certain portion of the populace “essential workers,” while the rest of us were asked to stay home for our own health and the health of those with compromised immune systems.

The earliest months of the pandemic’s impact here in the States were met with a crash course in epidemiology for those of us who’d managed to remain blissfully unaware up to now. Suddenly we were all ostensible experts in transmission. I recall leaving deliveries overnight and then using disposable gloves to open them when the time came. It seems like a dramatic overreaction months later as we’ve learned more about the virus’s ability to survive and spread outside the human body. But the question of how long it could live on an Amazon package was very much front of mind in March/April.

There’s a lot good things to be said about humans as a species. We’re uniquely intelligent and strange and we’re all beautiful and bizarre snowflakes. But we’re also disease vectors. For all of the questions surrounding the transmission of viruses on surfaces, it’s the humans who are doing the transmitting. It’s admittedly a fairly bleak lens through which to view the workforce, but these are the sorts of things you consider staring down the face of a virus.

Back in May we did an investor survey on the subject of robotics during the pandemic. It’s full of some great insight into where VCs minds were at seven or eight months back. At that point in time, there was still concern around Asia’s ability to ramp up manufacturing as the first sector to get hit by the virus. Even by then, however, things appeared to be returning somewhat to normal in areas like Shenzhen — and the emerging demand for the technology was clear.

“The current pandemic has only aggravated challenges addressed by robotics, including solving for labor shortages and augmenting worker productivity,” NEA’s Aaron Jacobson told TechCrunch. “Automation solutions are also critical for enabling supply chains to keep up with the current surge we are seeing in e-commerce. Even after we overcome the current wave of COVID-19 and life returns to ‘somewhat’ normal, there is still going to be a risk of disruption from future outbreaks. Deploying more autonomous solutions will help organizations strengthen the resilience of their operations.”

The highlighted categories are probably what you’d expect: food prep, delivery, fulfillment and telemedicine. They’ve all been reasonably popular categories in recent years, but the pandemic has undoubtedly compounded existing interest. Even now as it seems we can see a light at the end of the COVID-19 tunnel with the arrival of multiple vaccines, there’s still plenty of reason to assume this won’t be the last time we have to deal with this sort of thing during our collective lifetimes.

Take the delightfully titled, “Global Viral Outbreaks Like Coronavirus, Once Rare, Will Become More Common” that ran in The Wall Street Journal back in March. The story notes:

The incidence of infectious disease events has more than doubled from the 1940s to 1960s, according to EcoHealth Alliance, a New York-based nonprofit research group that built a database tracking disease events globally. The rate of such incidents surged in the 1980s with the advent of HIV and is now rising, says Peter Daszak, the group’s president.

Daszak goes on to use the word “exponential.” It’s not the sort of thing you want to hear from the head of a disease-tracking database. But it’s precisely the kind of society-altering event that investors need to be clued into.

Earlier in the year, Pitchbook noted a 57% increase in warehouse robotics investments in Q1. As the year draws to a close, The Robot Report notes that automotive (self-driving cars, et al) continues to be the big money maker for robotics investments this year, though logistics (Alibaba’s $1.3 billion acquisition of Cainiao) and medical robotics (MicroPort MedBot — $512 million raise) saw a lot of money change hands, while service/food prep and mobile robotics saw decent funding.

The truth is that, in many sectors, robots implementation simply wasn’t far enough along to genuinely cushion the blow. The demand for automating many sectors is clear, but it’s not as if companies could simply flip a switch overnight. In instances where robotic deployment has been successful, however, the technology has helped ease the burden on an impacted workforce.

Amazon, which has heavily invested in robotic fulfillment over the past decade, got a tremendous assist from its logistics robots. Healthcare workers — arguably the most necessary and at-risk segment during a pandemic — looked toward existing surgical robots to lessen the risk of transmission.

“Besides distancing the surgeon, today’s robotic systems typically require less staff in the operating room than with traditional open surgery,” the authors of a study titled “The rise of robots in surgical environments during COVID-19” write, “which reduces the personnel exposed to infectious aerosols, further reducing the risk of contamination. Fully contactless surgical suites must be considered in the light of the current pandemic.”

It’s difficult to know precisely when the next major pandemic will hit, but experts are predicting with a good deal of certainty that we can expect more of this sort of thing moving forward. Today’s push toward robotics and automation could help tomorrow’s workforce avoid buckling under that strain.