Most new homes that are being built in the U.S. today really aren’t all that different from those that were built 30 years ago. Some materials may be different, but most builders haven’t really kept up with the times. Y Combinator-backed Acre Designs wants to change this by building zero-energy homes that are outfitted with the latest technology.

Acre Designs is taking a page from the prefab home business, but puts a very modern spin on it. The company assembles all of the parts necessary to build one of its homes in a central warehouse and then packages them into a single shipping container. That alone removes a lot of the limitations of today’s prefab homes.

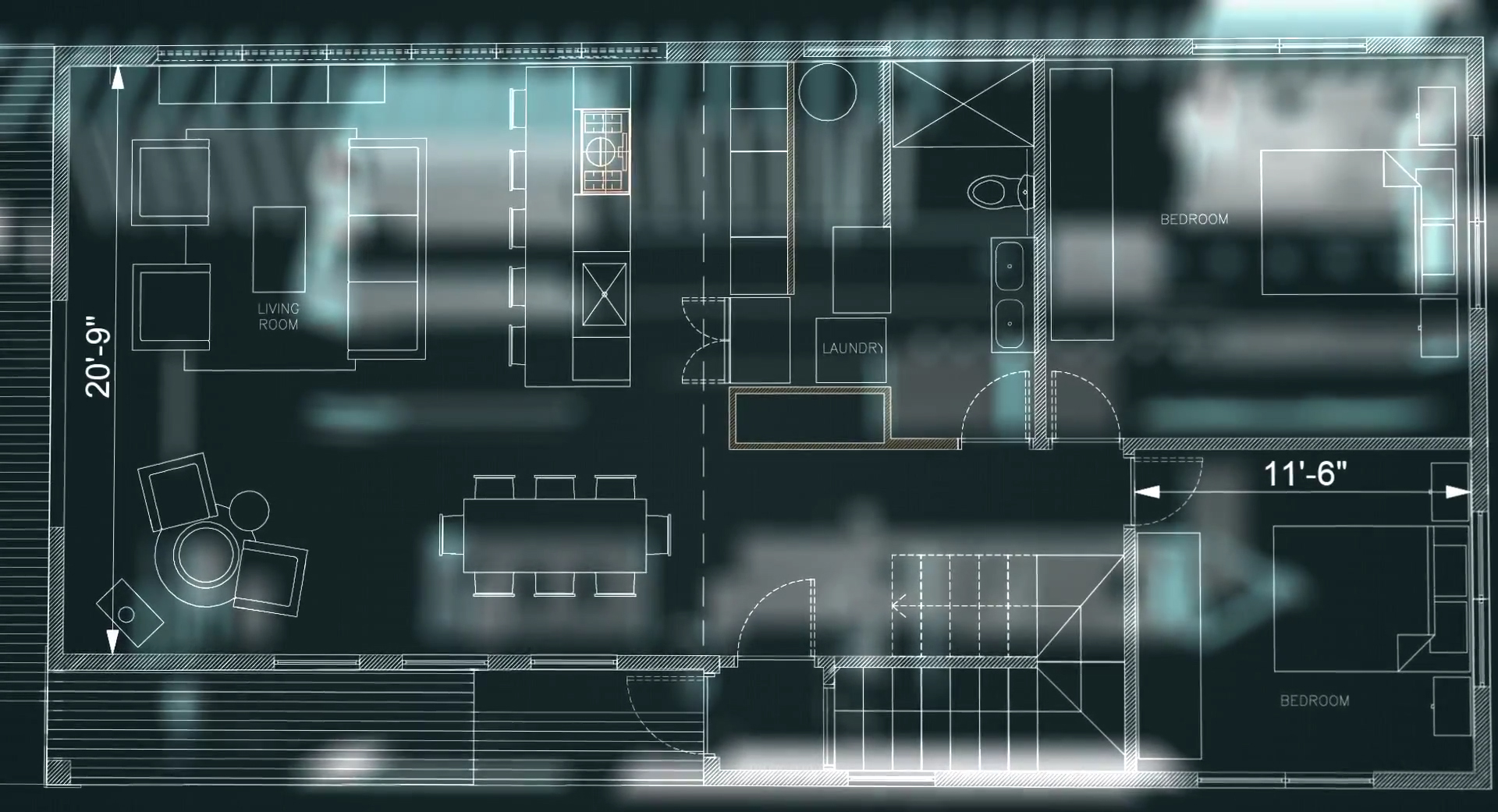

Acre is also mostly an online company, and buyers essentially buy their homes online. They have to provide their own land, but once they make their purchase decisions, a container will be dispatched to that site and Acre will work with local contractors to build the house to its specifications. Building one of these homes, which currently range from 1,100 to 1,800 square feet, should take about three months.

As Acre co-founders Jennifer and Andrew Dickson told me, they started the company out of their own frustration in finding a sustainable home that was built to modern standards. Specifically, they were looking for a zero-energy home that could use solar to power the entire house.

“We realized existing homes were very difficult to get to any standard of efficiency without a lot of work,” Jennifer told me. “But we are still building new homes with the same standards as 60 years ago.”

Andrew (an industrial designer with experience in working on everything from furniture to jet boats) and Jennifer (who has a degree in architecture and is Acre’s Chief Design Officer) co-founded the company with builder Don Newman (now Acre’s VP of Construction) and got accepted into Y Combinator. Building homes may seem like a bit of a stretch for a tech-focused accelerator like YC. In many ways, though, Acre represents the fringe of what could be considered a hardware startup, and YC has also recently started to think about projects that take on bigger societal challenges.

Given how outdated the construction process and many of the designs and features of today’s new construction homes often are, it’s a bit of a surprise that nobody has really tackled this market yet.

Andrew believes the reason for this is that the industry is very fragmented. Even the largest builders in California only build about 2,000 homes a year. “There’s tons of small guys and given the nature of how the industry works, the consumer doesn’t have a lot of choice,” he said. “You buy what’s on the market and what some builder cranks out. We are designers and we want things to be beautiful and functional as well. But then you see the process and quality — it’s atrocious.”

He also noted that because there aren’t really any brand names in the home-building market, there is very little incentive for builders to keep improving their products.

To fix this, Acre handles all of the front-end work of building the house and shipping the parts. Its containers include everything from windows to appliances and its smart-home technology. The local builders can then put these homes together in about 40 percent of the time it would take to build a regular home. Some of the time savings come from the fact that Acre already builds a tech and utility hub for the home, for example, so instead of having to have multiple trades come in to set these things up, the whole process becomes plug-and-play.

Compared to prefab builders like Blu Homes, Acre doesn’t have the overhead of a central manufacturing facility, and its shipping costs are significantly lower. Instead, the company partners with local contractors who know the business and local regulations (and who can function as ambassadors for Acre’s brand).

The company offers three plans. The smallest, a 1,200 square feet two-bedroom home, costs $400,000. A three-bedroom plan with 1,500 square feet costs $450,000 and the largest plan with four bedrooms and 1,800 square feet will set you back $500,000. That’s without the land. Depending on the local market, those are either relatively affordable prices (hello, California!) or extremely expensive homes.

Acre has already finished a couple of homes and expects to get to 300 to 500 houses per year in the next couple of years. The plan is to get to 2,000 homes in five years.

Once it gets a bit more scale, the team plans to launch a number of more affordable plans, too. The current ones are very much high-end homes with high-end appliances and finishes, so there is definitely some room for bringing down the price over time.

How likely are people to buy a home online, though? Both Andrew and Jennifer acknowledged that this remains a tough question to answer and that things would get easier once Acre has established itself as a brand. To get to that point, though, people will first have to experience their homes. One idea the company has is to work with existing owners to use their homes as Airbnbs, for example, so potential owners can test drive their homes before buying them.