I’ve stopped writing about a few things recently, mostly because of fatigue. First, I’m not that interested in merchants accepting bitcoin – these little blips are primarily PR moves and little else and I just don’t get as wound up about mass adoption of BTC as the true believers. I’m also not interested in covering crowdfunded 3D printers. Same problem: fatigue and little change in the real market or the real conversation.

And this is not to say that I won’t cover your printer, makers. I will. You just better have an amazing story to tell and, luckily, many of you do. But I digress.

Take a look at this article by one Chopmeister. He addresses a number of my main concerns in a very straightforward way. “Each minute you spend learning about 3d printing and 3d printers before you commit to buying one will save you a nerve or two in the long run,” he writes in a bit of tortured but important prose. “Don’t fall for the catchwords.”

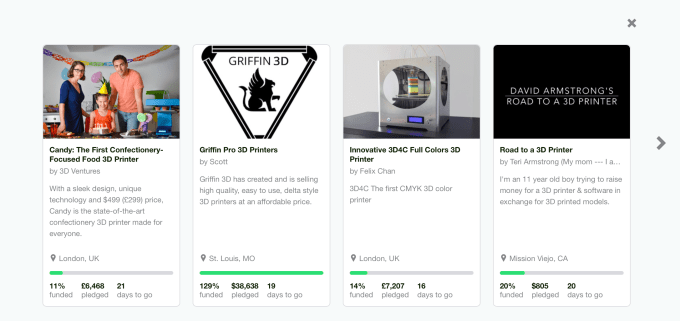

And that’s all these crowdfunded 3D printers are: collections of “catchwords” (buzzwords, that is) strung together on the back of a piece of cheap hardware built by manufacturers eager to cash in on the 3D printing craze. While there are many noble and remarkable efforts in this space and there have been many successes in the space, I worry that many of us fools may soon be parted from our money if we’re not careful (myself included.)

3D printing is about to be commoditized. I would argue that the best commodity printer – the Canon color laser printer of this whole industry – is the Makerbot and the quality and value fall quickly from there from the quite interesting (Zortrax, Monkeyfab, Afinia, Formlabs) to the overly-hyped (Buccaneer, Makibox), to the potentially fraudulent.

So where does that leave the rest of these printers? Nowhere, really. Once larger manufacturers like HP and Dell see a niche they can exploit, they will swoop in an offer a razors and blades solution for the home 3D printer. The reason they haven’t done this yet is manifold. First, before Stratasys bought Makerbot, there was no real market. A few dozen printers were sold per day and the entire market was taken up by home hobbyists who had little interest in dropping a few thousand for a ready-made unit.

Most major 3D printer manufacturers had an odd problem: demand was seemingly huge, and they received more orders than they could comfortably produce. But that was because they couldn’t commoditize the product enough to mass produce and thus depended on local, small manufacturers and even built the items in their offices. They were being drowned by demand but not because they were selling too many printers. They just didn’t have the cash to make those printers quickly enough to satisfy even the small number of orders they received.

A few very good companies avoided this trap early on and are doing quite well. Others buckled under the pressure. My concern is that more and more companies will buckle. Take a look at this excellent piece by Daniel Brown. Brown has estimated that the least expensive 3D printer still costs $300 to make, and most of that is in the rigid metal frame. While the nozzles and the electronics seem like the most expensive parts, they can be churned out en masse while many of these frames and cases are cut at great expense and hand-assembled. A guitar isn’t expensive because of the strings and the machine heads. It’s expensive because it’s expensive to make a body and neck that won’t warp or break. Brown writes:

Who is great at making cheap frames and cases? It’s not the guys at OrboPrinter++ or RepRapLite SuperFab. It will be Dell and Samsung and Monoprice who create 3D printers for the rest of the world. And when it happens it won’t be pretty for the little guys.

We can also argue whether Samsung will ever release a 3D printer. My engineer brother-in-law sees home 3D printers as hopelessly useless. He works for Honda and they have 3D printers the size of truck trailers spewing out parts. A Makerbot making a Yoda head seems like a frippery.

But this would be like the EIC of Random House laughing at the first (expensive) dot-matrix printers. “We do things so much more efficiently and with an eye for quality,” he’d say, sipping a highball (remember, this is a few decades ago). “Who needs a home printer when they have books you can buy at a store!”

Fast forward a few dozen years and now everyone can print letter quality pages at home, school, and in the office and the business case the Random House exec saw – the replacement of real printing presses by cheap home printers – didn’t come to pass. While he was chortling at inkjets, the industry was excavated out from under him. The same thing can happen with the manufacturers of injection molding systems, jewelry, and even some electronics. It will take a while, but it will happen. And all of this, the endless jostling, the posturing, and the endless noble effort, will reach its ultimate conclusion: the movement of 3D printing industry and the attendant printers as something to be covered every minute of every day to just another piece of hardware in the average home. I can’t wait.