A Danish company called Create It Real has built a software package that recognizes digital gun part models and prevents them from being printed. The software compares each piece you are attempting to print with a database of potential firearm parts and, the company notes, “for safety reasons, there are no models of firearms stored on the user’s computer but rather a list of characteristics.”

The CEO, Jeremie Pierre Gay, has created a proof-of-concept add-on to his turnkey, OEM 3D printing software that he is using to offering to other firms who would like to brand and sell a 3D desktop printer. “It will be possible make it as a service or integrate into another platform,” he said.

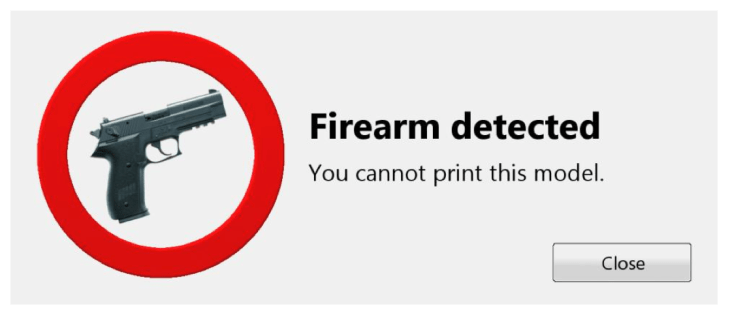

The program shuts down the modeling software if it senses that the user is trying to print a gun. Presumably this functionality can be shut down by the user and similar prohibitions – the algorithms that prevent the printing of currency in Photoshop – are often easily avoided. In short, Gay’s creation reduces liability for the printer manufacturer.

They have thus far input the data for the Liberator 3D printed handgun created by Defense Distributed as well as DefDist’s lower receiver part. However, they’re ready to add more parts to the package as they appear.

“We’ve made a test to make sure it will scale up to a much bigger database of parts,” said Gay. “It should be quite fast to actually check the model against the database.”

To Gay, the issue is less about gun control and more about management of risk. The system, for example, will allow a child to print a water gun but will stop him or her before they can print a real gun. It also allows Gay’s clients to add warnings to 3D printing processes so the printer maker can’t be held responsible.

“We are in the business of selling technology to quickly launch a desktop 3D printer,” said Gay. “If a buyer wants to print a gun, we want to be sure the 3D printer makers are not the ones responsible for it.”

The company is quite small and they are working with partners to bring their solutions to market. However, it’s an interesting solution to a thorny problem and shows just how complex the issue of 3D printing may soon become.