Two startups responsible for helping push the envelope on collaborative design and the democratization of building hardware are launching a competition today that could take open source 3D printing to the next level – and perhaps even into orbit.

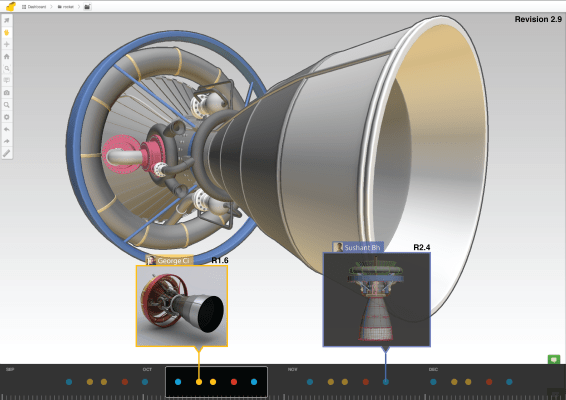

DIYROCKETS, the global space company co-founded by Darlene Damm and Diego Favarolo in 2012 to lower the cost of space exploration, and Sunglass, the TC Disrupt finalist and cloud-based 3D design platform founded by Nintin Rao and Kaustuv DeBiswas in 2011, today announced the launch of a competition to see who can build the best open source rocket engines via 3D printing. The goal of the contest is to prove that not only can well-funded private company projects like SpaceX contribute to extraterrestrial exploration, but so can anyone, with the help of open source, collaborative design and tools that make building rigorously engineered 3D tech affordable and accessible, regardless of budget or available PC hardware.

“The goal of DIYROCKETS is to lower the cost of building space technology through crowdsourcing and opensourcing,” Damm said in an interview. “So this particular contest is tackling the challenge of transportation in the space industry, because it’s one of the most expensive things. It’s very costly to transfer things from earth up into space.”

To accomplish those goals, this contest is designed to get teams to think about the problem of designing rocket engines with three key components in mind. Damm explained that the idea is to rethink how the space industry thinks about sharing information and technological developments, as well as tackling cost and building a solid tech foundation.

“In the space industry everything’s been so fractured in the past few decades that you don’t have collaboration and the benefits of that,” she said. “The second piece is that we’re trying to lower the cost through crowdsourcing and opensourcing the technology, so we’re asking that people submit a business case so that they’re not building some super expensive technology that’s not going to have any practical purpose. Third, we’re evaluating the technical side of the design.”

Eventually, the aim is to build an entire marketplace of opensource rocket parts from which engineers can choose from to build their own projects, and ultimately send those projects into space.

The competition will include three prizes, including a grand prize for best overall submission worth $5,000 for best design based on technical criteria, collaboration and business case. The second prize follows the same criteria but is specifically for student teams and is worth $2,500, and the third-place prize is also worth $2,500 and focuses solely on collaboration. In addition to those prizes, provided by Sunglass, there’s also a bonus offer from Shapeways, which is supplying free printing credits to all winners. All three winners will also receive free consulting from the Silicon Valley Space Center.

Even though there’s a prize specifically for students, Sunglass founder Nitin Rao explained that both parties expect to see participants from a wide variety of fields enter the race. The whole point of the project is to source good design and worthwhile input from wherever it may reside, regardless of any class/professional/monetary barriers that may have prevented some from participating in the past.

Once a winner is crowned, we’ll be well on the way to seeing a 3D printed rocket actually take flight, since everyone knows the rocket engine is the hardest part. Okay that may not be exactly true (I’m no expert), but it could still be the beginning of an exciting era for space exploration.